- Overview

- Basic Info.

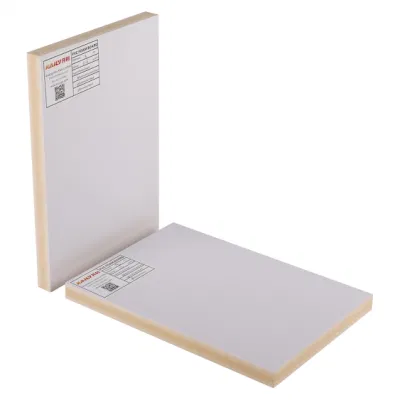

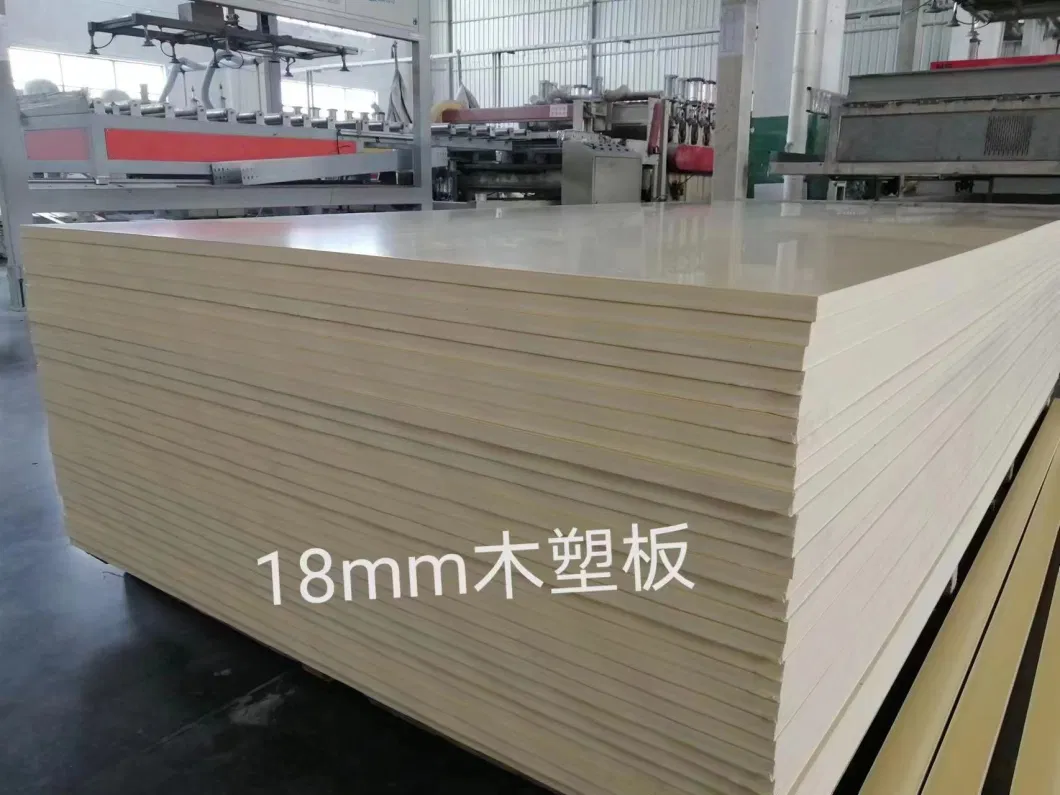

- Product Description

- Application

- Main Feature

- Packing and Loading

- How to use

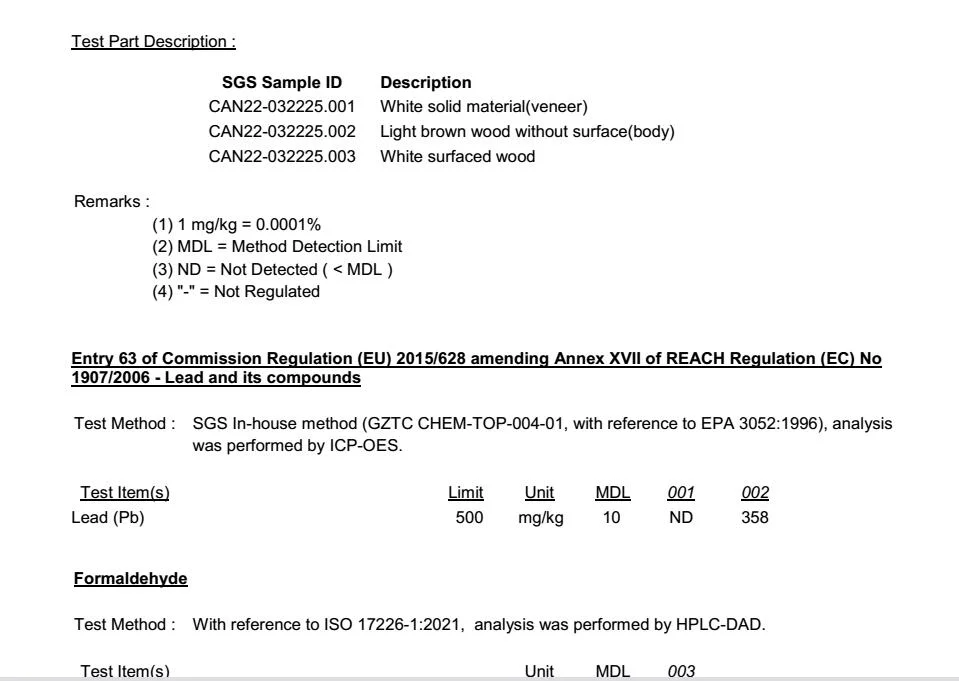

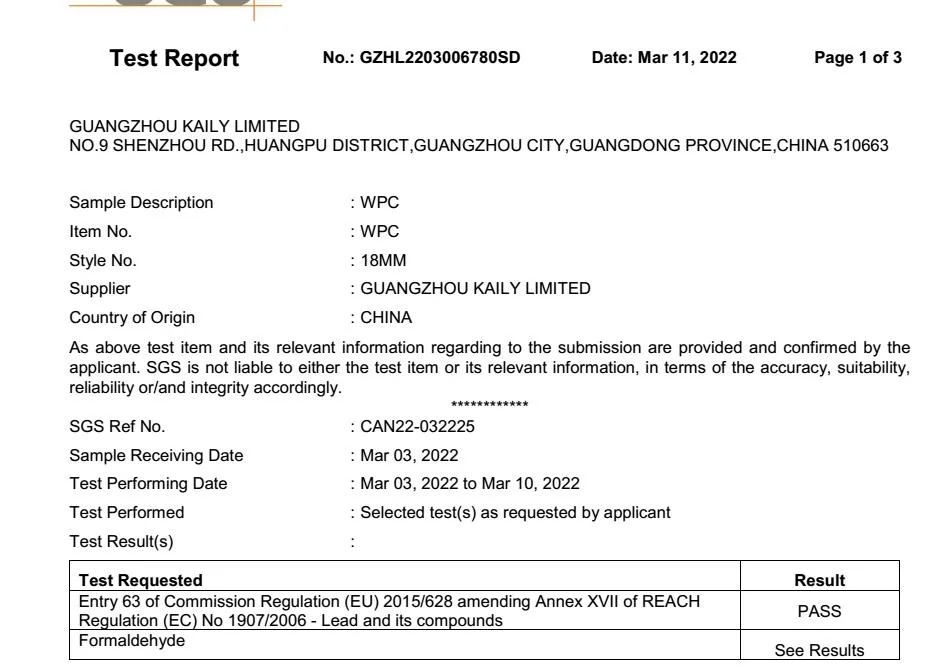

- Certifications

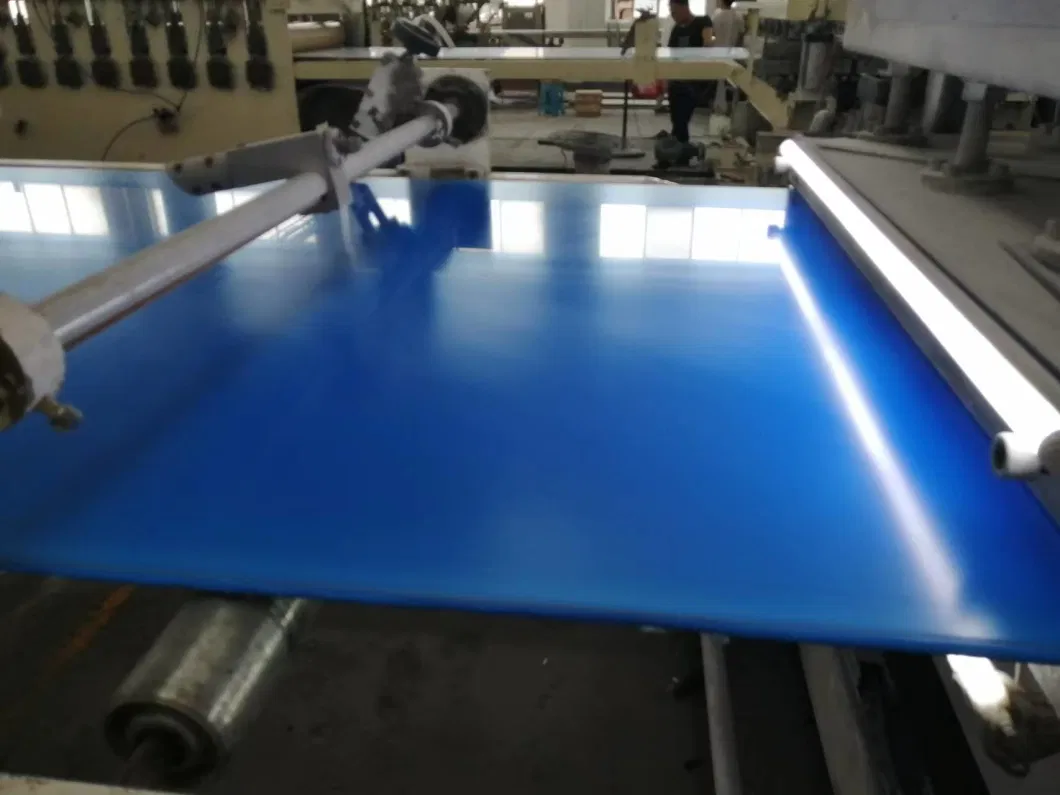

- Factory and Warehouse

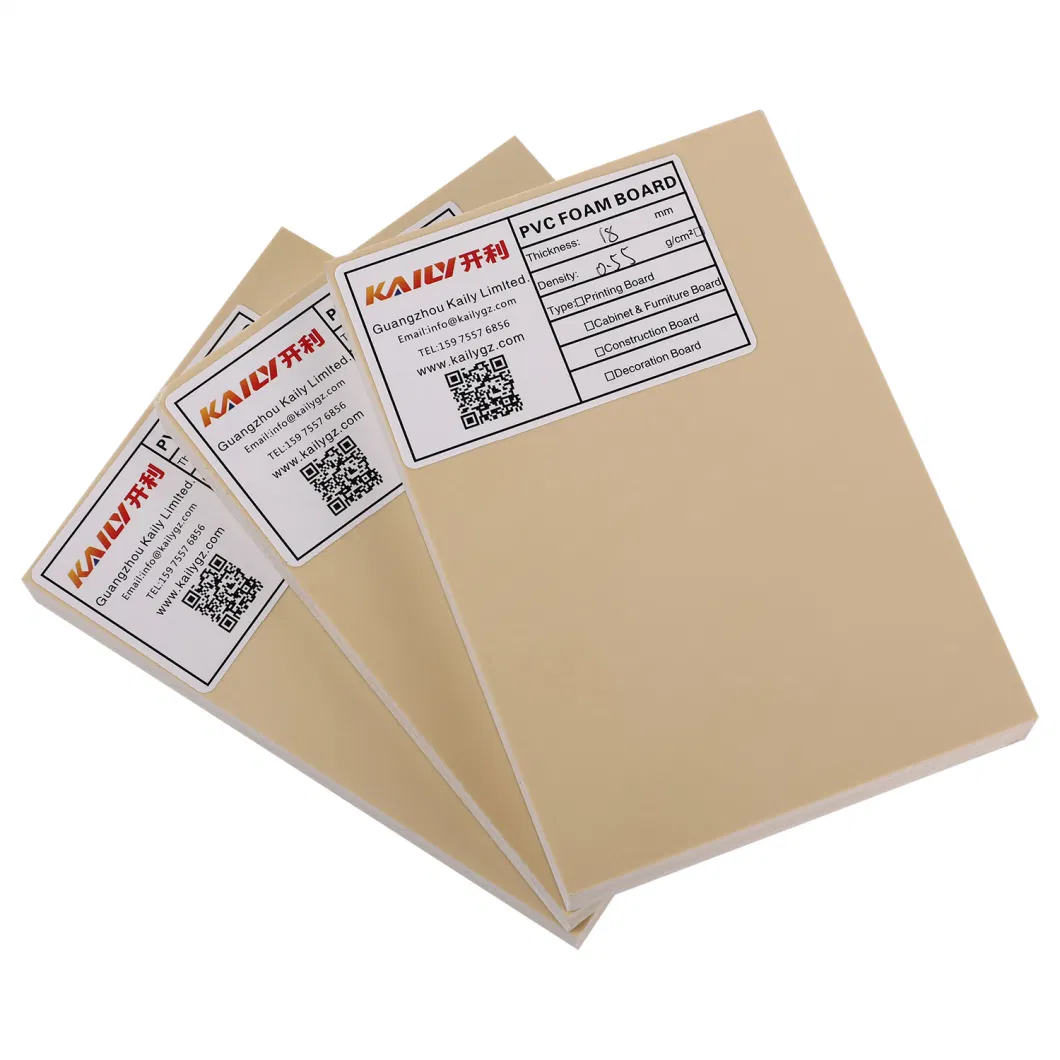

Basic Info.

Product Description

| WPC BOARD | ||||

| Specifications | Thickness(mm) | Color | Density(g/cm3) | Application |

| 1.22*2.44 | 3--38 | White/Colored | 0.4-0.8 | Furniture,Door, Decoration |

| 1.56*3.05 | 5--38 | White | 0.50-0.90 | Furniture,Door, Decoration |

| 2.05*3.05 | 5--38 | White | 0.50-0.90 | Furniture,Door, Decoration |

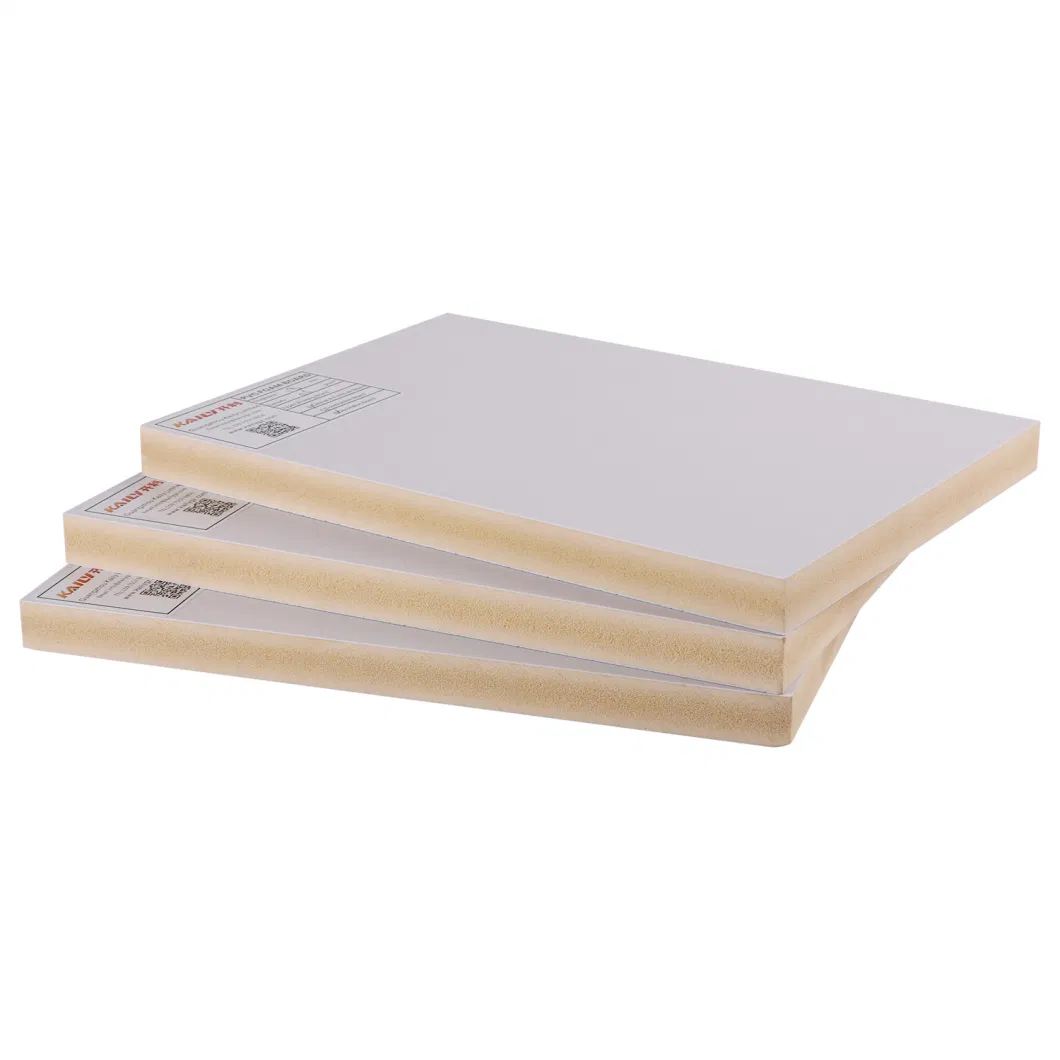

WPC foam board is a highly durable and safe material used for construction purposes. It is a mixture of wood fibers/wood flour and thermoplastics.WPC panels are also made of inorganic fillers and plastic composites. Wood and plastic composites can also be used as a strong, high-quality coating option. Next, the WPC foam board manufacturer will introduce the uses and advantages of WPC foam board.

WPC doors are used for flooring, decking, railings, fencing, landscaping, windows, doors, exterior or interior trim layers, manufacturing window, and door frames, preparing strong and well-designed structures, mixing floor furniture, etc.

In the modern era, the construction industry is also emerging with new materials due to daily technological and research advances, and this is no exception. One of these materials in the construction industry is Wood Plastic Composite (WPC). It is an ecological material that is replacing natural wood and plywood.

It is a composite material that constitutes a waste of wood fibers and thermoplastics. They are mixed to form a base material with a thick consistency. It is then extruded and molded into the different shapes and sizes required. In percentage terms, the WPC board contains 70% virgin polymer, 15% wood flour (fibers), and the remaining 15% additives.

WPC board has a wide range of uses and applications for outdoor deck flooring, fencing, door and window frames, and outdoor landscaping.

1. Outdoor decks.

It is used frequently on decks and outdoor patios. WPC manufacturers offer a variety of decking options such as solid decking, hollow decking, mosaic decking.

2. Fencing.

How safe and durable is the material? It is widely used in the preparation of garden fences and other uses for outdoor fencing.

3. Control panels.

This material is very durable and can be used in both interior and exterior panels since it is available in larger sizes.

4. Interior areas.

WPC boards are also used in interior areas for the manufacture of various furniture such as closets, kitchen cabinets, interior partitions, bathroom cabinets, and ceilings in rooms.

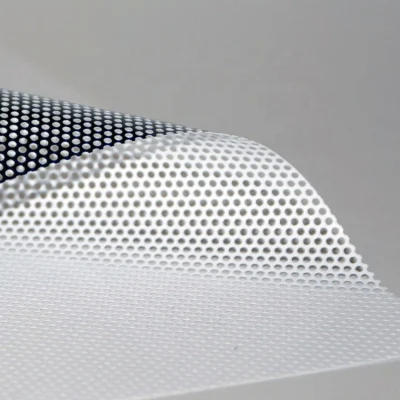

1. Waterproofing.

2. Heat preservation.

3. Excellent insulated.

4. Non-corrosion.

5. Non-toxic.

6. Light weight.

7. Fire retardant and self-extinguishing.

8. Tough, rigid with the high impact strength.

9. Good plasticity, being an excellent thermoform material.

10. Easy to clean and maintain.

·Plastic coating, membrane-stuck and printing

·With the usual equipment and tools, it can be processed again.

·Welding and bonding

·Cutting and sawing

·Bending when heated-up, thermal forming

Guangzhou Kaily Limited is a professional manufacturer and exporter that is

concerned with production and develop of PVC Foam Board, Wood/PVC composite Foam Board, PVC Co-extrusion Sheet,Acrylic sheet, Rigid PVC Sheet,PVC Moulding, PVC Trim.

Pofessional

Kaily have over 11 years experience and have been providing good service, good quality products and reasonable prices.All of our products are produced by advanced international level equipment and machinery.

Fast Shipping

Kaily have production line which 12 PVC foam board and 6 PVC Moulding ,4 Acrylic sheet, so we can deliver cargo fast.

Product Capacity

Kaily have 1 lamination machine and 3 CNC Carving machine,so we also can satisfied the different demands of customers for product processing.

ECO-Friendly

kaily raw material are led free,all product pass the SGS testing, so customers can use it with good confidence.

Reliable

Kaily QC department use full inspection management in production,all product will pass testing.

We hope to find a way to work with you,waiting for your contact to discuss the possible deal. 1, Q: Are you a manufacturer or trading company?

1, Q: Are you a manufacturer or trading company?

A: We are a professional manufacturer.

* 2, Q: How can I get the sample?

A: We can arrange sample for free.

* 3, Q: How long can I expect to get the sample?

A: We can prepare samples within 2 days. Usually it takes about 5-7 days for the delivery.

* 4, Q: What is your MOQ?

A: 20 GP container

* 5, Q: What colors can you make?

A: The white color is most popular. And we can customize special color according to your requirement.

* 6, Q: Can we have our Logo or company name to be printed on your package?

A: Sure. Your Logo can be putted on the film or package by printing or sticker.

* 7, Q: What is your lead time for mass production?

A: 10 days.

* 8, Q: What is your payment term?

A: T/T, L/C

* 9, Q: How do you pack it?

Carton packing, PE BAG PACKING ,WOODEN PALLET PACKING.

welcome to kaily!!