Basic Info.

Model NO.

TNN Series

Hardness

Rigid

Molding method

Multiple Extrusion

Other Material

PVC/Pet/PP/PC/PETG

Thickness

0.1mm to 1.5mm

Width

100-1300mm

Colors

Transparent /Glass/Clear Blue Tint/Amber/Orange

More Colors

White/Blue/Brown/Pink/Green/Yellow

Surface

Glossy

Form

by Roll or Cut Sheet Form

Outer Diameter

Max. 700mm

Inner Core Diameter

3"(76mm)

MOQ

1000kg

Quality Standard

ISO9001, RoHS, TDS,COA

Delivery

15-20days for One 20FT Container

Transport Package

Pallet

Specification

customization

Trademark

TNN

Origin

China

HS Code

3920620000

Production Capacity

500 Tons Per Month

Packaging & Delivery

Package Size

20.00cm * 10.00cm * 10.00cm

Package Gross Weight

10.000kg

Product Description

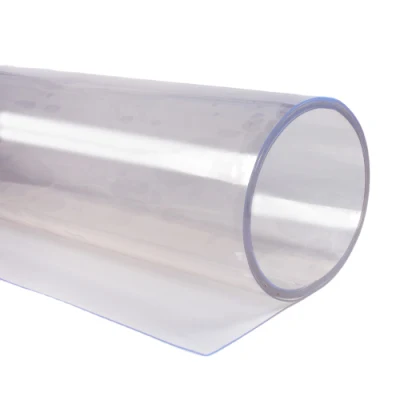

Clear Transparent Food Blister PET PVC Rigid Film Sheet Roll

COMPANY INTRODUCTION

Our factory has twenty years of R&D and production experience, through a number of certifications, obtained a number of national patents. Our engineers have rich production experience. Production of PVC film, PC film, PVC sheet, PET sheet, PP sheet, hips sheet. At present, it has 35 production lines, including 8 large-scale imported production equipment from Germany, Japan and the United States

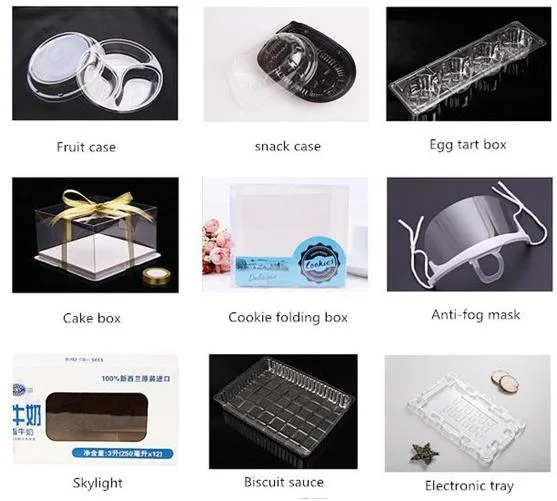

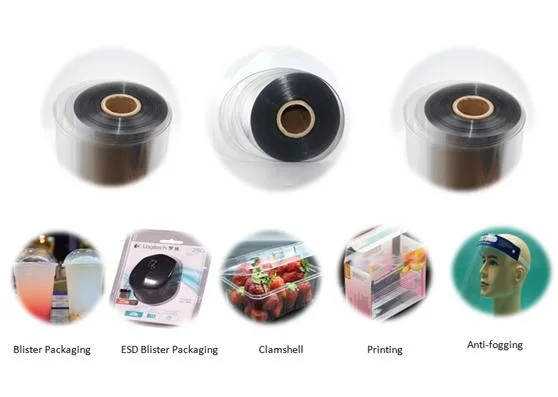

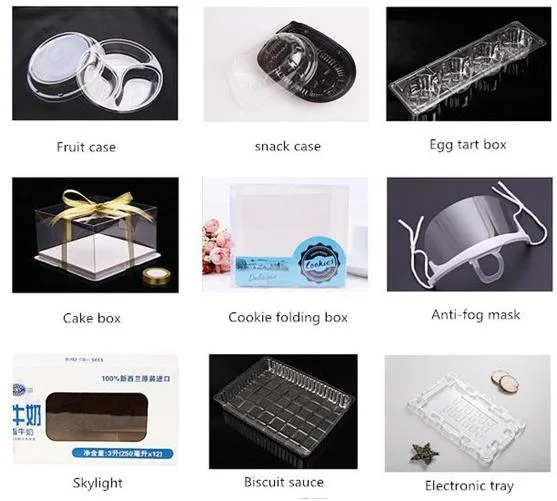

MAIN PRODUCTS

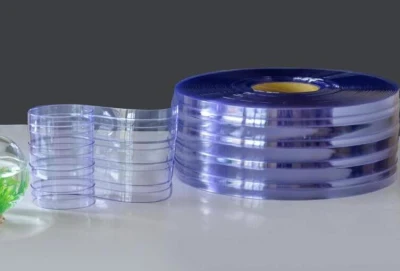

Our pvc film with excellent features of impact resistance and chemical resistance, According to customer request, we can produce film which are anti-static, UV resistance, smooth and high impact resistance, Can be used for packaging material of toys, tools and gift, folding box, decoration.

It used everywhere in life , can be used for vacuum forming, food packing, boxes folding ,uv offset printing ,screen printing, stationery, card cases, collection cards ,etc.

Production Equipment

Production Equipment

All line of productions are using auto feeding system and metering system

Computer numerical control technology It makes exact weighting precision

on the dispensing. (FIY: Liquid dispensing ±0.005kg)The line start from two-roll pilfer mill to 5 roll calender

All line of productions are computer auto controlled to effectively ensure the advance technology of products and long-term stability of quality

Finally finishing the roll by full auto winding machine. Max width 1300MM

We have 7 PVC production equipment ,so we will produce virgin ,color ,recycle on different equipment ,to make sure the stable quality ,other factory only have 1-2 production equipment ,so they have to produce all of quality in one machine ,so hard to control the quality .

Packing Management System

Every roll will paste roll label; Every pallet will paste pallet label.

PE film inside, Kraft paper outside, on pallets ,in 20ft container can be loaded about 20tons

2) PE film inside, Kraft paper outside, in 20ft container can be loaded about 25tons.

3) PE film inside, Carton box outside, in 20ft container can be loaded about 22tons

Delivery Inspection Management System

Our QC staff will sampling test according to standard, review check of label and product, QC check and provide delivery test report.

Before delivery, make sure that the goods are qualified. After the logistics department has been confirmed strictly.

Each step is photographed before delivery.

COMPANY INTRODUCTION

Our factory has twenty years of R&D and production experience, through a number of certifications, obtained a number of national patents. Our engineers have rich production experience. Production of PVC film, PC film, PVC sheet, PET sheet, PP sheet, hips sheet. At present, it has 35 production lines, including 8 large-scale imported production equipment from Germany, Japan and the United States

MAIN PRODUCTS

- 1. PVC Rigid Film

| Thickness | 0.10mm - 0.80mm(100micron - 800micron) |

| Width | 100mm - 1300mm |

| Colors | Transparent ,Glass clear ,Clear with blue tint,Amber color ,Orange color ,White color Blue color ,Brown color ,Pink color ,Green color,Yellow color |

| Transparency | Transparent,semi-transparency,opaque |

| Application | It is used for vaccum thermoforming food packing, folding packaging box,printing, can pack drug, food, hardware, motor and car fittings, toy, cosmetics, gift, garments etc. |

| Surface | Glossy |

| Form | by roll or cut sheet form |

| Hardness | Rigid |

| Outer diameter | ≤700mm |

| Inner core diameter | 3"(76mm) |

| MOQ | 1000kgs for clear PVC sheet 2000kgs for colored PVC sheet |

| Advantage | Used the first grade virgin material, uniform thickness, accurate size without any deviation, no scratch, less water waves and fish eye |

| Quality | Meet ISO9001, Rohs, TDS,COA |

| Packing | PE film inside ,Kraft paper outsider ,on pallets 20' container can be loaded about 20tons |

| Delivery | 15-20days for one 20'ft container |

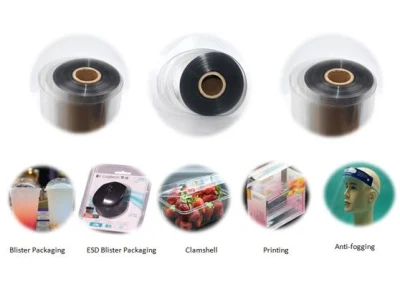

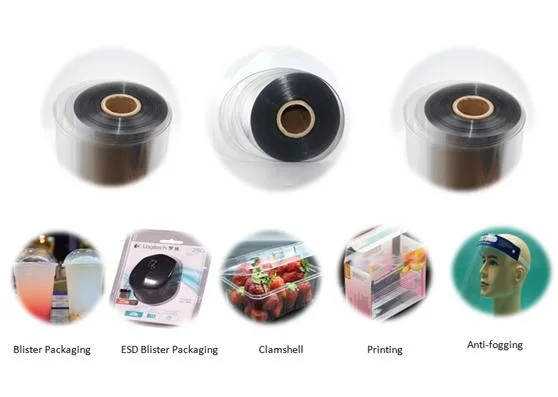

- 2. PET Rigid Film

Items | Features | Thickness (mm) | Width (mm) |

| General Thermoforming PET rigid sheet film | Good transparency, can make a variety of packaging such as hardware, toys, gifts, tools etc. | 0.20~1.50 | 200~1000 |

| Food Packing/Blister Packaging PET rigid sheet film | Good transparency, Compliance with health and safety regulations, applicable to all types of food and pharmaceutical packaging | 0.20~1.50 | 200~1000 |

| Anti-static Packaging PET rigid sheet film | Resistivity:105 ohm, applicable to the electronics or industrial packaging | 0.20~1.50 | 200~1000 |

| Folding Forming Packaging PET rigid sheet film | Transparent appearance, non-whitening when folding, applicable to processing and making box packaging such as toys, gifts cosmetics etc. | 0.20~1.50 | 200~1000 |

- 3. PP Rigid Film

Production Equipment

Production Equipment All line of productions are using auto feeding system and metering system

Computer numerical control technology It makes exact weighting precision

on the dispensing. (FIY: Liquid dispensing ±0.005kg)The line start from two-roll pilfer mill to 5 roll calender

All line of productions are computer auto controlled to effectively ensure the advance technology of products and long-term stability of quality

Finally finishing the roll by full auto winding machine. Max width 1300MM

We have 7 PVC production equipment ,so we will produce virgin ,color ,recycle on different equipment ,to make sure the stable quality ,other factory only have 1-2 production equipment ,so they have to produce all of quality in one machine ,so hard to control the quality .

Packing Management System

Every roll will paste roll label; Every pallet will paste pallet label.

PE film inside, Kraft paper outside, on pallets ,in 20ft container can be loaded about 20tons

2) PE film inside, Kraft paper outside, in 20ft container can be loaded about 25tons.

3) PE film inside, Carton box outside, in 20ft container can be loaded about 22tons

Delivery Inspection Management System

Our QC staff will sampling test according to standard, review check of label and product, QC check and provide delivery test report.

Before delivery, make sure that the goods are qualified. After the logistics department has been confirmed strictly.

Each step is photographed before delivery.