Basic Info.

Model NO.

THK: 0.3-1.8mm

HS Code

39204300, 39204300

Shipment

Within 15 Days

Sample

Free

Pinhole

No

Wrinkles

No

Bubbles

No

Lay Flat

Yes

Trace Mark

No

Phr

22-45

Transport Package

Rolls

Specification

SGS Reach RoHS EN71

Trademark

MC Plastic

Origin

China

Production Capacity

20, 000mt

Product Description

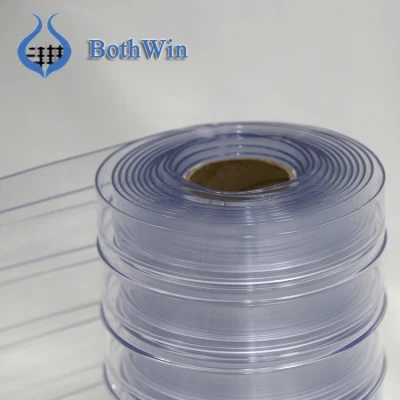

A: Surface Properties: Matte Glossy Transparent Translucent No pinholes No Bubbles No wrinkles No occluded air lay flat

B:Colors: Transparent or Print film as your design

C:Roll Specification : Thickness :0.3mm-3mm Width:500mm-1800mm

Length : customized

D:Packaging: Inside protective foam ,outside pvc film wrapped .

E:Standard or specific requirements: 16 Phthalates free .Non-toxic ,ECO-Friendly .our formulations depend on the requirements of customers: softness ,PHR ,UV property ,fire resistance and so on .

PVC Physical properties:

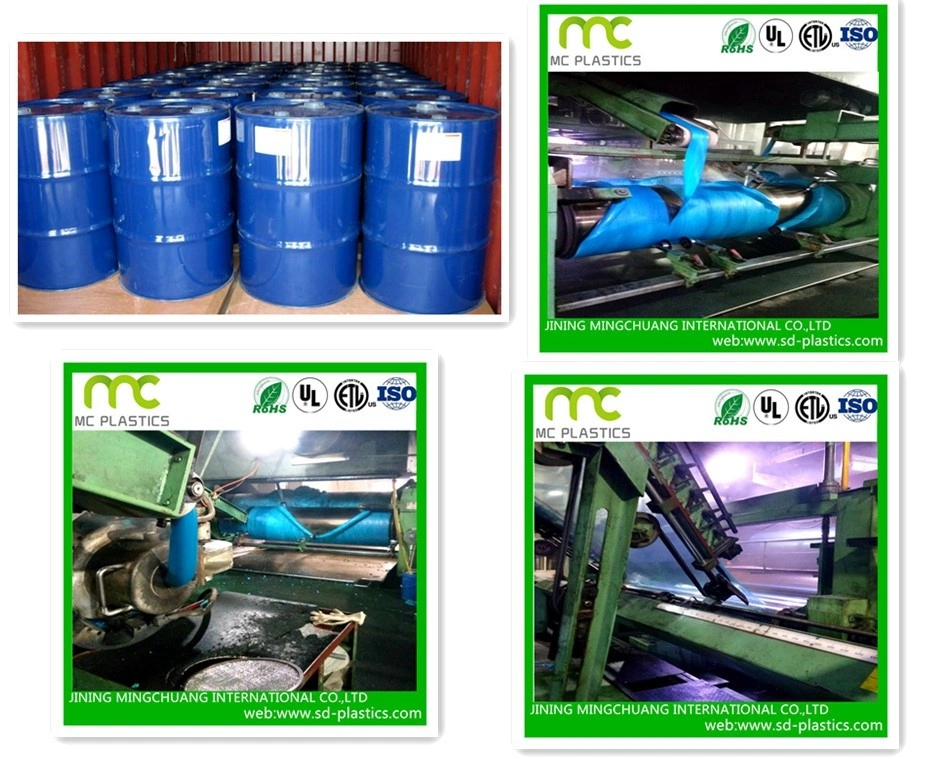

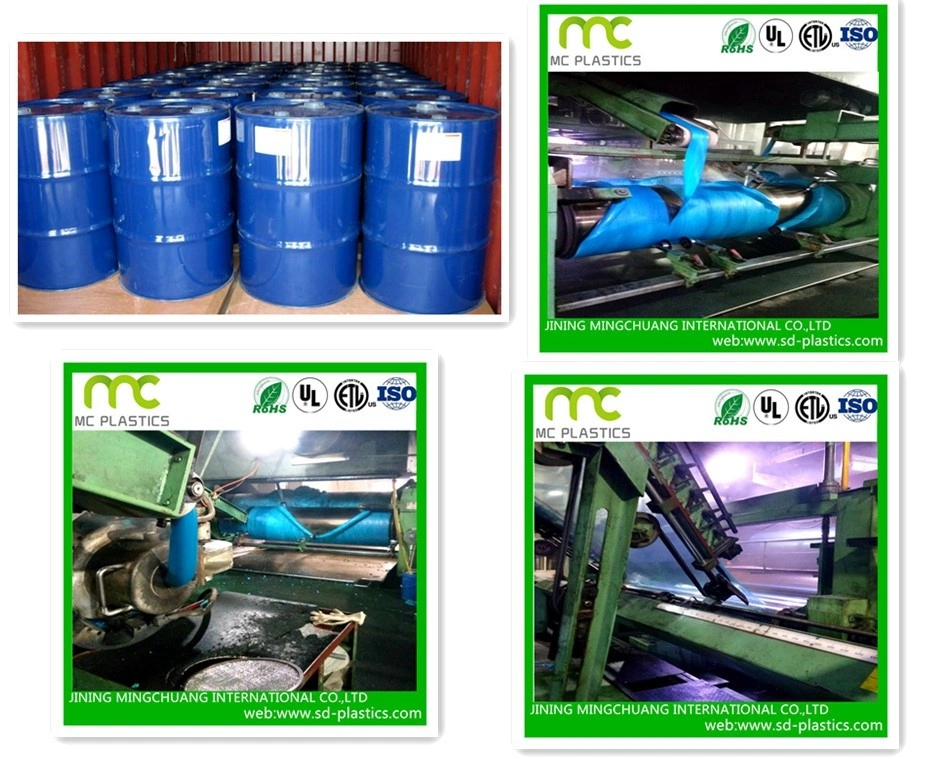

Process of PVC calendering sheet

B:Colors: Transparent or Print film as your design

C:Roll Specification : Thickness :0.3mm-3mm Width:500mm-1800mm

Length : customized

D:Packaging: Inside protective foam ,outside pvc film wrapped .

E:Standard or specific requirements: 16 Phthalates free .Non-toxic ,ECO-Friendly .our formulations depend on the requirements of customers: softness ,PHR ,UV property ,fire resistance and so on .

PVC Physical properties:

| Item | Index | |||||||||||

| Mulch Film | Printing film | Outdoor film | Industrial film | Inflatable toy film | Insulation tape film | Others | ||||||

| TOP Quality | First Class | Second Class | TOP Quality | First Class | Second Class | |||||||

| 1 | Tensile Strength(MD CD)MPa | ≥16.0 | ≥16.0 | ≥13.0 | ≥11.0 | ≥16.0 | ≥14.0 | ≥11 | ≥16.0 | ≥16.0 | ≥22.5 | ≥15.0 |

| 2 | Elongation at break(MD CD)% | ≥210 | ≥160 | ≥150 | ≥180 | ≥200 | ≥180 | ≥130 | ≥200 | ≥220 | ≥200 | ≥180 |

| 3 | Elongation at low Temperature(MD CD)% | ≥22 | ≥8.0 | ≥8 | ≥8 | ≥30 | ≥25 | ≥8 | ≥10 | ≥10 | ≥10 | |

| 4 | Angle tearing strength(MD CD)% | ≥40 | ≥40 | ≥35 | ≥30 | ≥40 | ≥35 | ≥30 | ≥40 | ≥40 | ≥40 | ≥45 |

| 5 | Dimensional stability(MD CD)% | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤6 | ≤7 | ≤5 | ||

| 6 | Heating Loss % | ≤4.0 | ≤6.0 | ≤6.0 | ≤6.0 | ≤4.0 | ≤4.0 | ≤4.0 | ≤3.0 | ≤4.0 | ≤4.0 | |

Process of PVC calendering sheet

- PVC Resin SG-3 Or SG-5 ,K Value 60-75 .

- Mixed process: PVC resin with Plasticizer, Lubricants, stabilizers ,pigments and filler. From mixer or mill ,then the extrusion .

- Four-Roll calendering process which compresses and rolls the plastic into a flat film or sheet. Finishing equipment cooling and take-off the films with embossed or plain rolls.

- Finished rolls.

- Inspection ,can test surface, tensile strength ,plasticizer extraction/migration, elongation ,flame-retardant, breakdown and so on .

- Packing and shipping.