- Overview

- FAQ

Basic Info.

Model NO.

RWP-638

Surface Finishing

PVDF, PE, Powder Coating, Anodized, etc.

Density of Rock Wool

80kg/M³, 100kg/M³, 120kg/M³

Usage

Building, Wall, Partition, Ship Hull, Roof, Store

Shape

Rectangle, Triangle, Rhombus, Trapezoid

Transport Package

Standard Export Packages--Wooden Crate

Specification

1200*2400mm, customized made

Trademark

HongZan

Origin

Foshan, China

HS Code

76169990

Production Capacity

500, 000 Sqm Annually

Product Description

Fireproof Insulation Material Rock Wool for construction material

HONGZAN production lines & Capacity:

1. Product Introduction

Basic Information:

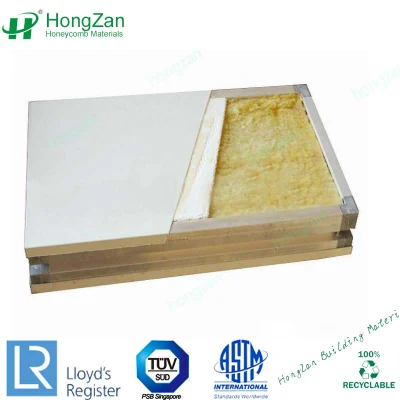

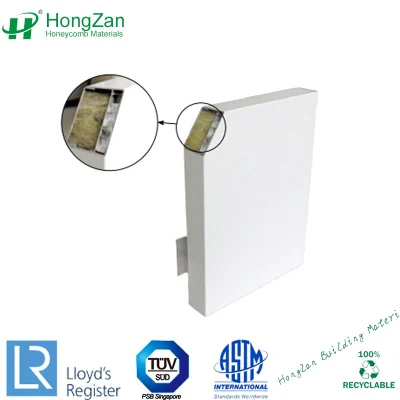

Rock Wool Composite Panel, composited by aluminum panel / galvanized steel and rock wool. With the high quality and efficient thermal insulation, sound insulation and sound absorption features, rock wool composite panel can be widely used in interior or exterior wall, partition, vessel, bunk bed, heat exchanger, freezer, cold room, etc.

Specification:

The density of rock wool is customized, and the top and bottom sheets can be aluminum, galvanized steel, stainless steel, etc.

Technical Data:

According to current production process, rock wool panels can be divided into sedimentation rock wool panel, pendulum rock wool panel and three-dimensional rock wool panel, its performance specifications are as below:

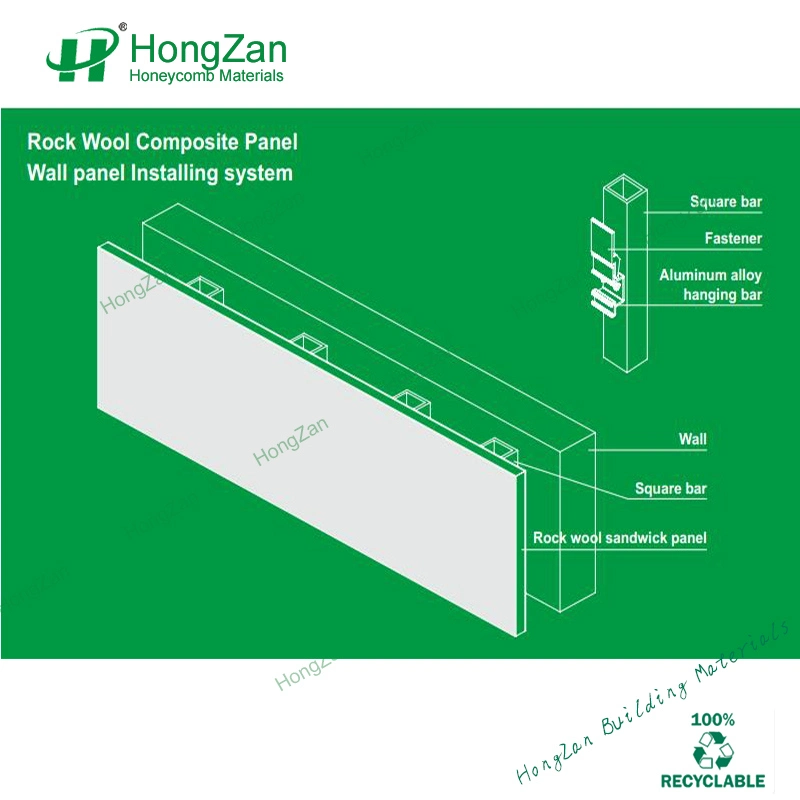

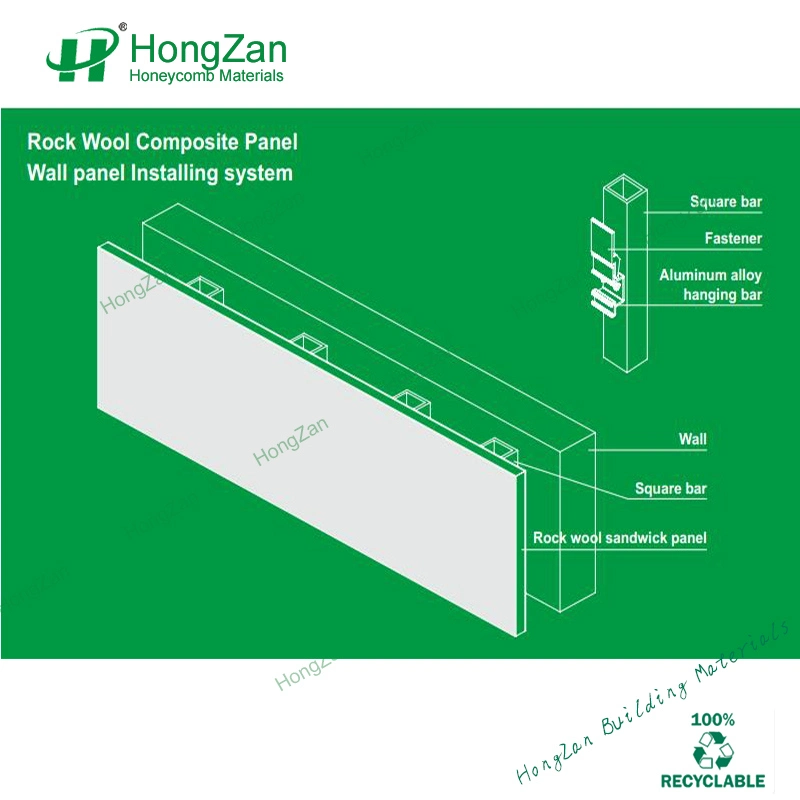

Rock Wool Composite Panel Wall Panel Installing System:

Advantages:

The advantages of Rock Wool Composite Panel are including:

High quality and efficient thermal insulation, sound insulation and sound absorption.

Compare to the traditional insulation materials, Rock Wool Composite Panel with outstanding light density, thermal conductivity, non-burning, non-toxic, fire-proof, chemical stability, long life cycle, cold-insulation, etc.

2. Application

Rock wool sandwich panel with good performance of heat and sound insulation is widely used for interior or exterior construction decoration, such as below:

3. Package Details

Hongzan will use standard export packages--wooden crate which will largely protect the products well during land/sea/air/train transportation. Customized package requirements are available.

4.Certificates

Hongzan has obtained international recognized certificates and test reports for aluminum honeycomb panel related to Fire rate, sound insulation, and so on, E.G.:

1), ISO 9001:2008;

2), A class fire rate by Lloyd's ( Marine Association) ;

3), BS 476 ,475 by TUV PSD Singapore;

4), EN13501-1 by ITS;

5), ASTM by ITS.

1. Do you provide free samples ?

yes, we do supply sample for free.

2. Do you offer best price?

We are manufacturer with our own export right, we always provide our best price with high quality products.

3. How can you ansure your quality is reliable?

We have our QA system and pass ISO 9001:2008; , besides, our products passed BS, IMO, CE EN, ASTM tests. We can supply reports, certificates, You are also welcome to send QC team to do the inspection.

4. How about your factory's productivity ability?

Our production capacity is 50000 square meter per month.

5. Can we have video factory tour and live show of your factory during this pandemic time ?

Dear, of course! You are welcome to set up a life video visitng of our factory !

5. Contact Details

Victoria

mobile: 0086 139 2319 2421

HONGZAN production lines & Capacity:

| Aluminum honeycomb panels | 500,000 sqm annually |

| Aluminum honeycomb core &corrugated core | 4.5 million sqm annually |

| Stone (marble,granite) & Ceramic honeycomb panel | 80,000 sqm annually |

| FRP honeycomb panel | 100,000 sqm annually |

| Rock wool Sandwich panel | 100,000 sqm annually |

| Solid aluminum sheet | 300,0000 sqm annually |

Product Description

1. Product Introduction

Basic Information:

Rock Wool Composite Panel, composited by aluminum panel / galvanized steel and rock wool. With the high quality and efficient thermal insulation, sound insulation and sound absorption features, rock wool composite panel can be widely used in interior or exterior wall, partition, vessel, bunk bed, heat exchanger, freezer, cold room, etc.

Specification:

The density of rock wool is customized, and the top and bottom sheets can be aluminum, galvanized steel, stainless steel, etc.

| Top Steel Thickness | 0.3-0.8 mm |

| Bottom Steel Thickness | 0.3-0.8 mm |

| Regular Thickness of Panel | 50/60/75/80/100/120/150/175/200 mm |

| Regular Width of Panel | 950/1000-1100/1150 mm |

| Available Density of Rock Wool | 80/100/120/125 kg/m³ |

| Surface Texture and Appearance | samll wave, flat, embossment, big rib, etc. |

| Regular Surface Treatment | PVDF,PE,HDP, SMP, etc. |

| Perforation | Yes (customized) |

| Applications | Wall cladding(exterior & interior), partitions, ship hull, roof, tunnel, etc. |

| Customerization(MTM) | Yes (color, surface texture, size, shape, pattern, etc.) |

Technical Data:

According to current production process, rock wool panels can be divided into sedimentation rock wool panel, pendulum rock wool panel and three-dimensional rock wool panel, its performance specifications are as below:

| Items | Index | ||

| sedimentation rock wool panel | pendulum rock wool panel | three-dimensional rock wool panel | |

| Density (kg/m³) | ≥150 | ≥150 | ≥150 |

| Density tolerance allowed (%) | ±15 | ±10 | ±10 |

| Average diameter of fiber (μm) | ≤7 | ≤7 | ≤7 |

| Coefficient of heat conductivity (W / (m*k)) | 10ºC-≤0.036≤0.036 | 50ºC-≤0.039≤0.039 | 70ºC-≤0.044≤0.041≤0.041 |

| Shot content (diameter>0.25mm) (%) | ≤12.0 | ≤6.0 | ≤6.0 |

| Volume humidity absorption (%) | ≤5 | ≤1.0 | ≤1.0 |

| Volume water absorption (merged in water) (%) | - | ≤4.0 | ≤4.0 |

| Hydrophobicity (%) | ≥98 | ≥98 | ≥98 |

| Heat shrinkage temperature (ºC) | ≥600 | ≥650 | ≥350 |

| Organic content (%) | ≤4.0 | ≤4.0 | ≤4.0 |

| Compression strength (kPa) | >10 | ≥40 | ≥60 |

| Peel strength (kPa) | >6 | ≥14 | ≥22 |

| Burning behavior class | A | A | A |

| Application scope | under 20 m | under 100 m | under 100 m |

Rock Wool Composite Panel Wall Panel Installing System:

Advantages:

The advantages of Rock Wool Composite Panel are including:

High quality and efficient thermal insulation, sound insulation and sound absorption.

Compare to the traditional insulation materials, Rock Wool Composite Panel with outstanding light density, thermal conductivity, non-burning, non-toxic, fire-proof, chemical stability, long life cycle, cold-insulation, etc.

2. Application

Rock wool sandwich panel with good performance of heat and sound insulation is widely used for interior or exterior construction decoration, such as below:

- Construction, such as roof panel, outdoor wall panel, etc.

- Vessel / ship, such as passenger ship, cruises, freighter, etc.

- Pipeline

- Storage tank

- Distillation tower

- Boiler

- Flue

- Heat exchanger

- Fan and travel and other industrial equipment

- Constant temperature room, cold room / freezer

3. Package Details

Hongzan will use standard export packages--wooden crate which will largely protect the products well during land/sea/air/train transportation. Customized package requirements are available.

4.Certificates

Hongzan has obtained international recognized certificates and test reports for aluminum honeycomb panel related to Fire rate, sound insulation, and so on, E.G.:

1), ISO 9001:2008;

2), A class fire rate by Lloyd's ( Marine Association) ;

3), BS 476 ,475 by TUV PSD Singapore;

4), EN13501-1 by ITS;

5), ASTM by ITS.

Q & A for concerning:

1. Do you provide free samples ?

yes, we do supply sample for free.

2. Do you offer best price?

We are manufacturer with our own export right, we always provide our best price with high quality products.

3. How can you ansure your quality is reliable?

We have our QA system and pass ISO 9001:2008; , besides, our products passed BS, IMO, CE EN, ASTM tests. We can supply reports, certificates, You are also welcome to send QC team to do the inspection.

4. How about your factory's productivity ability?

Our production capacity is 50000 square meter per month.

5. Can we have video factory tour and live show of your factory during this pandemic time ?

Dear, of course! You are welcome to set up a life video visitng of our factory !

5. Contact Details

Victoria

mobile: 0086 139 2319 2421