- Overview

- Product Description

- Related Product

- Our Services

- Company Profile

Basic Info.

Packaging & Delivery

Product Description

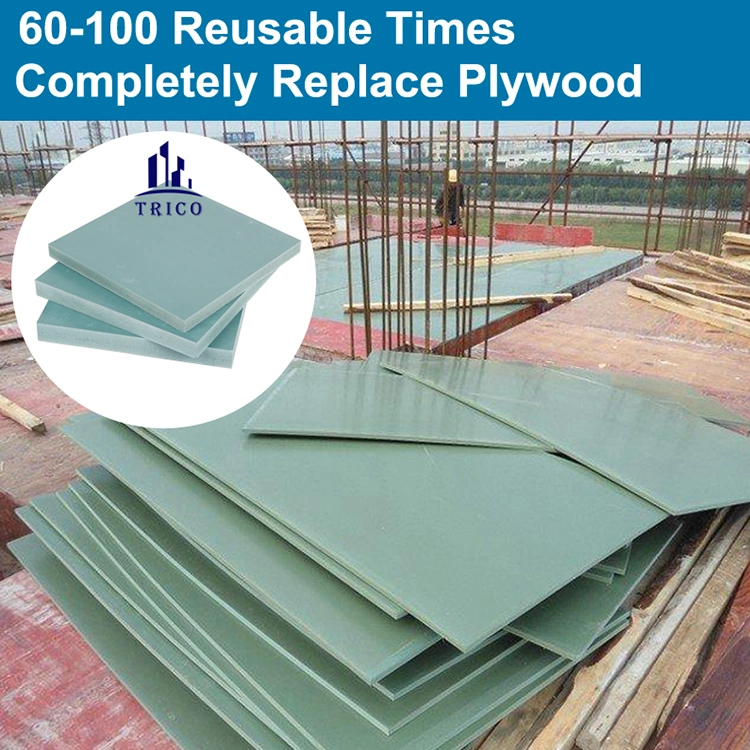

Hebei TRICO Formwork Panel Formwork Board PVC Plastic Formwork Board

For Concrete Formwork

What is PVC Plastic Formwork?

• PVC Plastic Formwork is a new type of plastic formwork.

• It has the same sizes and applications as plywood formwork, but with much better

performance. In wooden structures, it can be reused at least 50 times. In premium

structures which provide good protection for the formwork panels, it can be reused many

more times.

•This new PVC Plastic Formwork is in accordance with the world trend of energy

conservation and environmental protection.

• Energy-saving with its environmental protection and economic with its cyclic regeneration,

this product is gradually replacing traditional formwork materials.

Characteristics & Advantages

Save Cost by Reusing 50+ Times!

PVC Plastic Formwork can be reused ≥ 50 in plain wooden structures, and many more times in

premium metal structures. This means the lifespan of 1 piece of PVC Plastic Formwork equals

that of 5~10 pieces of plywood formwork.

Antiflaming

No wood powder or any material from different resources is added so the PVC Plastic Formwork is

anti-flaming. This effectively reduces the fire risk and limits the spread of fire. There is no need to

implement additional fire

precautions and protection measures on the site.

| Size | Weight | Packaging | 20GP Quantity | 40HQ Quantity |

| 913×1830×12mm | 12±0.5kg | 75pcs/pallet | 900pcs | 1800pcs |

| 1220x2440x12mm | 22±0.5kg | 75pcs/Pallet | 600pcs | 1200pcs |

| 1220x2440x14mm | 27±0.5kg | 65pcs/Pallet | 520pcs | 1000pcs |

| 1220x2440x15mm | 30±0.5kg | 60pcs/Pallet | 480pcs | 950pcs |

| 1220x2440x18mm | 37±0.5kg | 50pcs/Pallet | 400pcs | 750pcs |

| If Special Sizes need, please contact with us! | ||||

Testing report for our PVC plastic formwork

NO. | Parameters | Standards | Results |

1 | static bending intensity | ≥18MPa | 21MPa |

2 | elasticity modulus | ≥1200MPa | 1600MPa |

3 | alkali resistance | No bubble, no cracking | No bubble, no cracking |

4 | charpy impact strength | ≥12.0KJ/m2 | 29.9KJ/M2 |

5 | Maximum load retention | ≥80% | 96% |

6 | Water absorption rate | ≤2.5% | 2.2% |

7 |

Variation Rate Of Heating Sizes

| Horizontal:-0.10% | -0.14% |

| Vertical: -1.05% | -1.33% | |

8 | FR performance | B1 | B1 |

Why Choose TRICO'S PVC Formwork?

Advantages 1: 100% New Pure PVC Material-No Recycled Material

As mentioned, adding any second-hand, recycled PVC material will lead to unqualified

UV Resistance in PVC plastic formwork, especially in heavy UV areas including USA, Europe,

South America, Oceania, Africa and some Asia areas.

Advantages 2: Best Nail Holding Strength

Even if you nail less than 5mm from the edge, our product will still hold the nails well with

no cracking.This is also because we use 100% new pure PVC material. With this unique

advantage, we can control our PVC Plastic Formwork to have the best tenacity and rigidity.

Formwork Tie Rod System

Concrete Formwork Tie Rod System is used with various formwork accessories in concrete

construction. Tis system includes Tie Rod, Formwork Wing Nuts, Concrete Anchor Nuts, Hex

Nuts,Connection Nuts, Washer Plates, Formwork Wedge Clamps, Formwork Spring Clamps,

Water Stopper/Water Barrier Nut, Combi Plate Nut, Plastic Cones, Plastic Tubes, etc.

All of these items are popularly used for concrete formwork & shuttering systems, including

wall formwork, column formwork, slab formwork, beam formwork, etc.

Formwork Clamp is a high-strength concrete forming system designed for fast-paced gangform

operations. It has the strength required for the large contact areas and fast pour rates common

in large gangform applications.

We have carbon steel spring clamp and spring clamp tensioner, ductile cast iron wedge clamp

and weged clamp tensioner. Formwork Clamps fit for 6-10mm or 8-12mm steel rebar.

- Formwork Tie Rod System

- Aluminium Formwork Wall Tie System

- Scaffolding System

- PP Hollow Plastic Formwork

- Steel Formwork Panel with Plywood Forming System

- Other Plastic Building Materials

1. Quality: Strictly control the quality through three levels. First level, quality test on the producing line.

Second level, quality test during warehousing. Third level, quality test before loading.

2. Timeliness: 24 hours online. Provide consulting and quotation services for customers all the time.

3. Veracity: Strictly follow the customer standard to ensure the tolerance range and meet customer's

requirement.

4. Integrity: If the customer complains about the quality of the products, our company will actively

cooperate with them to solve the problem. If it is the responsibility of our company, we will bear the

corresponding responsibility and compensation.

5. Longevity: Establish good long-term relationship with customers.

TRICO was founded in 2002. As an expert in the field of formwork and scaffolding, TRICO is

committed to providing better products and services to customers in the global construction

industry.TRICO has a wide range of product lines, including the production and supply of full

system of building formwork, scaffolding and related components, and has realized the "1+N"

one-stop service mode. The products sell well in more than 90 countries and regions, winning

the recognition and trust of business partners around the world.

TRICO's R&D team is experimenting and optimizing products every day. The endless

improvement and perfection is the gene of TRICO culture. TRICO's mission is to promote the

quality improvement, cost reduction and environmental protection and efficiency enhancement

of global buildings.Let's work together to make it easier to build houses anywhere in the world!