Basic Info.

Model NO.

SG8

HS Code

3904109001

Production Capacity

500t/Month

Product Description

Features:

It has the outstanding feature of abundant raw material ( oil/limestone/coke/salt/natural gas),mature manufauturing process,low price,extensive usage, it has become the second general resin next yo the PE resin, take up 29% amount of consumption of the world synthesis resin. PVC is mainly used for making the artificial leather,film,trunking and so on the plastic soft products, also can produce panel,doors and windows,pipeline and valve and so on the plastic hard products.

Unique features:

1.rain-proof,,fire-resistant,antistatic electricity, easy to molding.

2.low input high output

Technique:

the normal production line composes the roller press,printing press,back coating machine, cutterbar

Application:

1.General soft production, use extruer can make soft pipe,electric cable,electric wire and so on. Use injection make-up machine fit to various kinds of mould can make plastic sandals ,sole,slipper,toy,car accessories and so on.

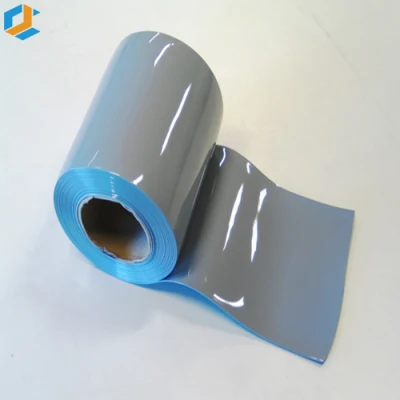

2. PVC film, packing bag ,raincoat,tablecloth,curtain,air-filled toy and so on.

3. PVC coating products, leather suitcase, portfolio, the cover of book, the cushion of sofa and car, also plastic flooring.

4. PVC foam products foam slipper, sandal, insole, shockproof material

5. PVC transparent cut

6. PVC resin coat hanger hand shank christmas tree

7. PVC panel and hardness plank

8. PVC wood material, steel construction material, hollow container

| Tape: | SG1 | SG2 | SG3 | SG4 | SG5 | SG6 | SG7 | SG8 |

| K value | 77-75 | 74-73 | 72-71 | 70-69 | 68-66 | 65-63 | 62-60 | 59-55 |

| Viscosity, ml/g | 156-144 | 143-136 | 135-127 | 126-119 | 118-107 | 106-96 | 95-87 | 86-73 |

| Average polymerization | 1350-1250 | 1250-1150 | 1100-1000 | 950-850 | 950-850 | 750-650 | ||

| Number of impurity particle≤ | 30 | 30 | 30 | 30 | 30 | 30 | 40 | 40 |

| Volatiles content %,≤ | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 |

| Appearing density g/ml≥ | 0.42 | 0.42 | 0.42 | 0.42 | 0.42 | 0.45 | 0.45 | 0.45 |

| Residual after sieve 0.25mm mesh≤ | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| 0.063mm l≥ | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Number of grain/400cm2≤ | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Plasticizer absorbency value of 100g resin | 25 | 25 | 25 | 22 | 19 | 16 | 14 | 14 |

| Whiteness %,≥ | 74 | 74 | 74 | 74 | 74 | 74 | 70 | 70 |

| Residual chlore thylene content mg/kg≤ | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Ethylidene chloride mg/kg≤ | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |