Basic Info.

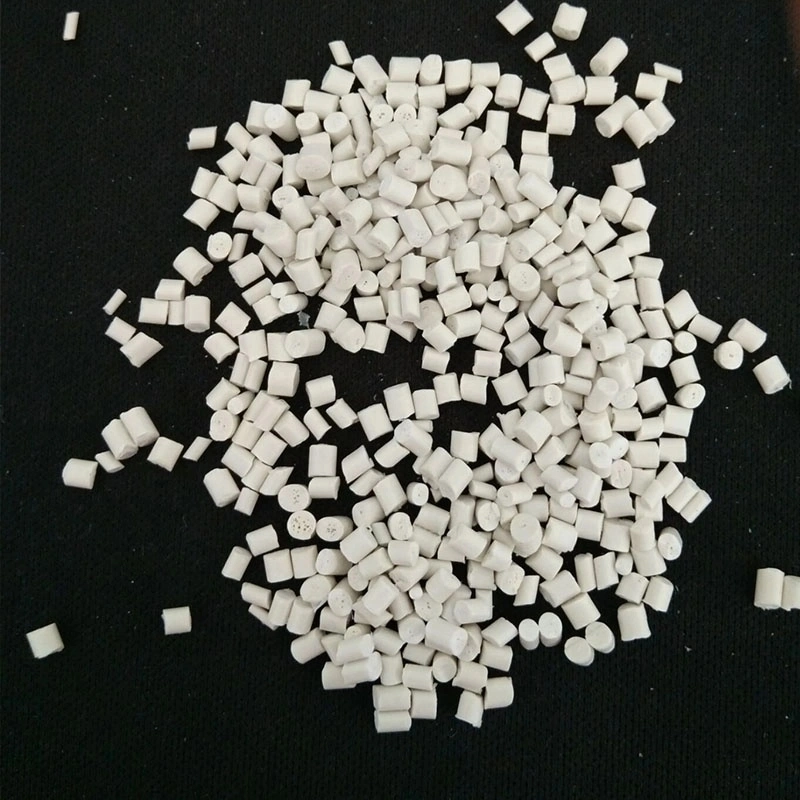

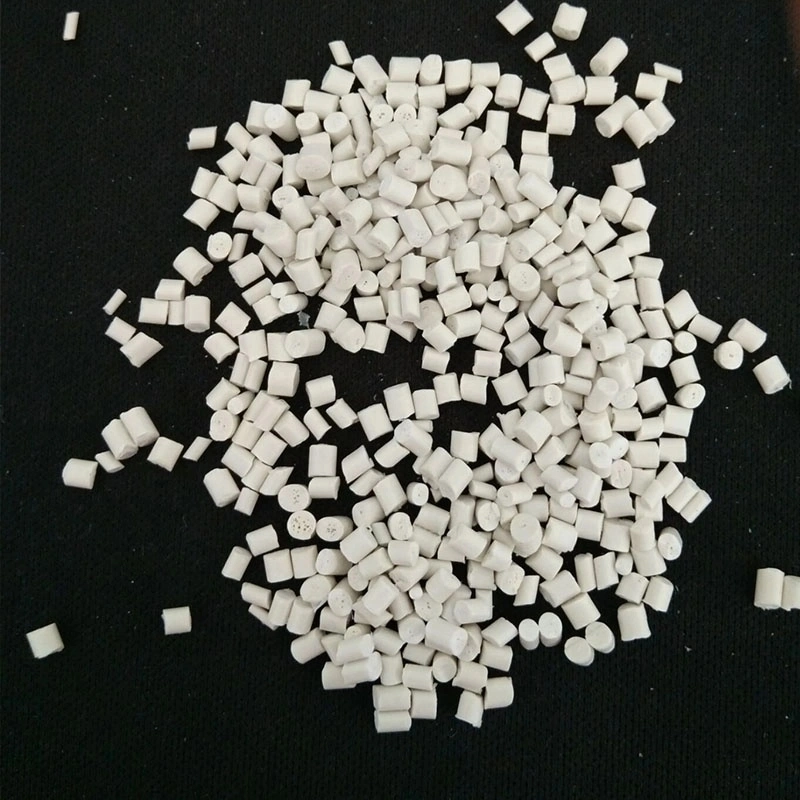

Model NO.

PA66

Colour

White

Usage

General Plastics, Engineering Plastics, Specialty

Plastic Forming Method

Injection

Shape

Pellet - Granules

Feartures

High Impact, High Strength, Hightoughness, Anti-UV

Transport Package

Bag

Specification

25kg/bags

Trademark

China

Origin

Hebei

HS Code

3901901000

Production Capacity

500 Ton Per Day

Product Description

1.Product Description

PA66 chemical name: polyadipylenediamine, commonly known as nylon 66. It is a kind of colorless and transparent semi-crystalline Thermoplastic, which is widely used in automobile, electronic and electrical appliances, mechanical instruments, industrial components and other industries. However, because of its high water absorption, poor acid resistance, low impact strength at dry and low temperature, and easy deformation after water absorption, nylon affects the dimensional stability of the product, and to some extent limits its application. In order to improve the above shortcomings, expand its application fields and better meet the requirements of performance, people use various methods to modify PA66, to improve the impact, thermal deformation, processability and chemical corrosion resistance of Pa66 plastics. Because the specific strength and Young's modulus of glass fiber (GF) are 10 ~ 20 times larger than PA66, the linear expansion coefficient is about 1/20 of PA66, the water absorption is close to zero, and it has the characteristics of heat resistance and chemical corrosion resistance, therefore, glass fiber filling is a common method of PA66 reinforcement and modification. PA66 is widely used in PA series because of its high mechanical strength. Due to its high crystallinity, its rigidity and heat resistance are high.

2.Application

Translucent, opaque, milky white crystalline polymer with plasticity. Density 1.15 g/cm 3. The melting point is 252 ° C. The brittleness temperature is -30 °C. The thermal decomposition temperature is more than 350 °C. Continuous heat resistance of 80-120 ° C, equilibrium water absorption of 2.5% . Resistant to acids, alkalis, most inorganic salt aqueous solutions, halogenated alkanes, hydrocarbons, esters, and ketones, but soluble in polar solvents. It has excellent wear resistance, self-lubrication and high mechanical strength. However, because of its high water absorption, the dimensional stability is poor. Applications: widely used in the manufacture of mechanical, automotive, chemical and electrical equipment parts, such as gear, roller, pulley, roller shaft, pump in the impeller, fan blades, high-pressure seal shell, valve seat, washer, bushing, various handles, support frame, steel wire cladding. The film can also be made into a packing material. It can also be used to manufacture medical devices, sports equipment, daily necessities, etc. . The application of nylon 66; nylon 66 is mainly used in automobile, mechanical industry, electronic and electrical appliances, precision instruments and other fields. In terms of end use, nylon 66 is used in the automotive industry, with electronics in second place. About 88% of nylon 66 is processed into various products by injection molding, and about 12% of nylon 66 is processed into corresponding products by extrusion blow molding.

| PA66 | ||

| Brand/Grade | Relative viscosity | Features & Usage |

| EPR22 | 2.20-2.30 | Good fluidity, low viscosity, suitable for plastic modification |

| EPR27 | 2.67±0.03 | Medium viscosity, used for injection molding or as a modified plastic, can also be used for spinning brown silk, staple fiber and other spinning industry. |

| EPR34 | 3.35-3.45 | High viscosity, injection molding, extrusion, electrical and electronic applications |

| EPR32 | 3.19-3.21 | High viscosity, high gloss. Injection molding, extrusion, also can be used for different purposes of the multifilament extrusion, flame retardant V-2, especially suitable for flame retardant modification |

| FYR27 | 2.70±0.03 | Medium viscosity, spinning grade, can be used to spin nylon 66 brown silk, tow, staple fiber, carpet silk and other products, can also be used for nylon 66 modified base material |

| PA66 I | 2.5-2.7 | This product is widely used in the field of national economy, as the base material of engineering plastics for many special purposes, it can be made into various products by adding various materials and is widely used in industry, aerospace, automobile, textile and other fields. Properties: This product is a translucent or opaque milky crystalline polymer. Excellent wear resistance, self - lubrication, high mechanical strength. Resistant to acid, alkali and halogenated alkanes. |

| PA66 II | 2.7-2.9 | |

| PA66 III | >2.9 | |

| Toughened / Reinforced / Flame-retardant PA66 | ||

| Brand/Grade | Filler | Features & Usage |

| AG15 | 15% Glass fiber | High fluidity, rapid prototyping. Electronic and medium - rigid mechanical parts, shields, wind wheels, etc. Good surface finish. |

| AG33H | 33% Glass fiber | Easy injection molding, used for electronic and electrical skeleton and high rigidity and thermal stability of industrial parts, fan blades and electrical insulation parts, good surface finish. Can replace DuPont 70G33L, A3EG6, A3EG7etc. |

| AG50H | 50% Glass fiber | Ultra high strength, anti-warping, dimensional stability, heat resistance; For size-stable industrial parts requiring high rigidity; Can replace long glass fiber reinforced nylon 66, can replace A3EG10, DUPONT 70G50L etc. |

| AG30HSL | 30% Glass fiber | Thermal stability, excellent rigidity, strength and long-term heat resistance, suitable for automotive industry and other industrial components requiring long-term heat resistance. Can replace A3WG6, AG30HSL-BK70, A3WG6 , BK20560 |

| AG30HSF | 30% Glass fiber | Thermal stability, excellent rigidity, strength and long-term heat resistance, suitable for automotive industry and other industrial components requiring long-term heat resistance.The surface is better than AG30HSL. Can replace AKV30G H2.0 SR1. |

| AG33ZSW | 33% Glass fiber | Used for ball head connection between metals, free rotation, not locked, with excellent self-lubrication, heat resistance, wear resistance, low temperature resistance, fatigue resistance |

| AG33UV | 33% Glass fiber | With high fluidity, outstanding toughness, weather resistance, uv resistance, and good rigidity, easy processing, good surface finish. Used for anti-uv and anti-aging industrial parts. |

| AG43H | 43% Glass fiber | With high strength, high rigidity, anti-warping, stable size, good surface, used for automotive industry parts and power tools parts. Can replace DUPONT 70G43L |

| AG50HSL | 50% Glass fiber | Long term heat resistance. |

| AG60H | 60% Glass fiber | For industrial components requiring ultra-high rigidity |

| AWG35U | 35% Glass fiber | Water meter, high strength threaded pipe fittings and pump parts. Uv resistance, hydrolysis resistance, good surface finish. |

| AWG45 | 45% Glass fiber | Specially designed for water meters and pipe connections |

| A28S | / | Rapid forming, no post-processing, good stability, wear resistance, especially suitable for coated metal parts |

| A28HSL | / | Injection grade, rapid prototyping, heat stable. Used for shell, support frame, gear, roller, electronic and electrical parts that need long-term heat resistance. Can replace DUPONT 103HSL |

| A408HSL | / | Excellent impact resistance, thermal stability, long-term heat resistance, Can replace DUPONT A408HS |

| A27UV | / | It has excellent uv resistance, weather resistance, cold resistance, and excellent mechanical properties. Can be used for high-grade motorcycle, automobile exterior decoration. |

| AFN-1 | halogen-free flame retardant,V-0 | Environmental protection halogen-free flame retardant, with excellent flame retardant and electrical properties. Used for high-end electronic connectors, connectors, switches and other components. Can replace asahi chemical INTO FR370, Toray CM3004-V0 |

| AFR50 | 25% Glass fiber, Flame retardant,V-0 | High fluidity, heat resistance, high rigidity. Similar to DUPONT FR50 for low warping frame, relays, electronic and electrical parts |

| AFRG0R-1 | Flame retardant,V-0 | It has high glowing wire ignition temperature, high flame retardant, and excellent mechanical properties and excellent injection molding and rapid demoulding. For electronic and electrical products requiring high hot wire, unattended electrical components and other high-end fields |

| AFRG10R-2 | 10% Glass fiber, Flame retardant,V-0 | With high flame retardant, high hot wire, high heat resistance and high mechanical properties, low warpage and good toughness. Suitable for high-end electronic connectors and other components. The material is reused for four times, and its performance still remains high stability. |

| AFRG20R-2 | 20% Glass fiber, Flame retardant,V-0 | Heat resistance, high rigidity. Used for low warping and flame retardant parts, such as electronic components, coil support, lamp assembly, etc. The quality is equal to that of imported materials |

| AFRG25RZ-2 | 25% Glass fiber, Flame retardant,V-0 | With outstanding high flame retardant, high hot wire, stable heat resistance, cold resistance and high mechanical properties, excellent impact resistance. It is used for high-end electronics, motors, household appliances and other industrial parts which need good rigidity, good stability, low warpage and good toughness, and it is more suitable for the parts with very complicated structure. Fast demoulding, very low production cost, suitable for automatic injection molding, normal production will not produce defective products, with a very high cost performance. |

| AFRG25X1 | 25% Glass fiber, Halogen-free red phosphorus flame retardant,V-0 | With good comprehensive performance, used for flame retardant, warping resistance, cold resistance, electronic appliances and automobile industrial parts .Can replace A3X2G5 |

| AFRG30X | 30% Glass fiber, Halogen-free red phosphorus flame retardant,V-0 | With good comprehensive performance, used for flame retardant, warping resistance, cold resistance, electronic appliances and automobile industrial parts . |

| AFRG35X1 | 35% Glass fiber, Halogen-free red phosphorus flame retardant,V-0 | With good comprehensive performance, used for flame retardant, warping resistance, cold resistance, electronic appliances and automobile industrial parts .Can replace A3X2G7 |

| A25L | / | Pure nylon 66. Rapid molding, rapid demoulding, stable size, high fluidity, used for thin wall products and complex structure of the parts |

| A28L | / | Pure nylon 66, injection grade, rapid molding, rapid demoulding, size stability. Used for connectors, electrical and electronic parts, ties and other injection molded parts, can replace A3k, 101F,1300S |

| A3H-4 | / | Pure nylon 66, injection grade, rapid molding, rapid demoulding, size stability. Used for high torsion screw, nut, shaft, shaft, gear and other high strength parts. |

2.Application

Translucent, opaque, milky white crystalline polymer with plasticity. Density 1.15 g/cm 3. The melting point is 252 ° C. The brittleness temperature is -30 °C. The thermal decomposition temperature is more than 350 °C. Continuous heat resistance of 80-120 ° C, equilibrium water absorption of 2.5% . Resistant to acids, alkalis, most inorganic salt aqueous solutions, halogenated alkanes, hydrocarbons, esters, and ketones, but soluble in polar solvents. It has excellent wear resistance, self-lubrication and high mechanical strength. However, because of its high water absorption, the dimensional stability is poor. Applications: widely used in the manufacture of mechanical, automotive, chemical and electrical equipment parts, such as gear, roller, pulley, roller shaft, pump in the impeller, fan blades, high-pressure seal shell, valve seat, washer, bushing, various handles, support frame, steel wire cladding. The film can also be made into a packing material. It can also be used to manufacture medical devices, sports equipment, daily necessities, etc. . The application of nylon 66; nylon 66 is mainly used in automobile, mechanical industry, electronic and electrical appliances, precision instruments and other fields. In terms of end use, nylon 66 is used in the automotive industry, with electronics in second place. About 88% of nylon 66 is processed into various products by injection molding, and about 12% of nylon 66 is processed into corresponding products by extrusion blow molding.

1.Packing:

In 25kg PP woven bag, Water-Proof Plastic Bag.All products are accepted OEM orders to satisfy your special request,as the packing and loading.Customized Service is available.

2.Storage:

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air.

3.Transportation:

During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

4. Factory Show

We have Our own factory , the factory mainly produces plastic pellets and has more than ten years of experiences. The factory is a private factory integrating, production, research and development and wholesale.Our main products are:PE,PP,EVA,HDPE,LDPE etc.The products are widely used in Engineering plastics, chemical industry other fields. Based on honesty, praised by the public!

5. company Introduction

Hebei Fashen Trading Co., Ltd. was founded in 2019.

Our company is located in Shijiazhuang City, Hebei Province, China.We can supply PP, PC, ADS and other plastic raw materials and rubber.

Headquartered in Xingtai City, Hebei Province, China, the company is a large rubber and plastic production enterprise.

Our advantage is to have experienced foreign trade team and strong production capacity and supply capacity.

We can accept T/T, L/C, Weston through transport and other different terms of payment.

We can supply different types of plastic raw materials and rubber.

Our factory has been exporting products for many years.

Products are exported to Southeast Asia, South America, Africa, Australia and other countries and regions.

Our products are of high quality and favorable price, and are well received by many countries in the world, and we have established good long-term business relations with many customers.

Since its establishment, the company has always adhered to the business principle of talents and integrity, gathering industry elites, advancing with The Times and constantly optimizing to provide customers with a full range of services, so that the company has always maintained its competitiveness in the fierce market competition.

Company on the basis of absorbing domestic and foreign advanced technology and process, set the wisdom and experience, continuously improve product accuracy, stability, reliability, and always adhere to provide customers with the best products, best service, best reputation, to a place of professional pre-sale, sale, after-sales service has won the domestic and foreign customers trust and praise, the company insist on technological innovation, on the basis of Pay close attention to quality management, constantly improve the service level, to achieve the benign development of the company's business. Hebei Fashen Import & Export Co., Ltd. 's products have been exported to all over the world, favored by customers, but also willing to become your most reliable long-term partner.