- Overview

- Product Description

- Application

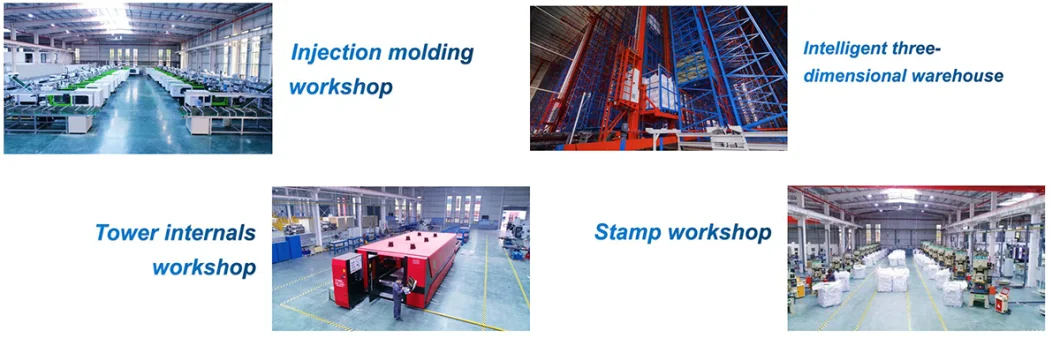

- Workshop

- Certifications

- Our Partners

- Why choose us?

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

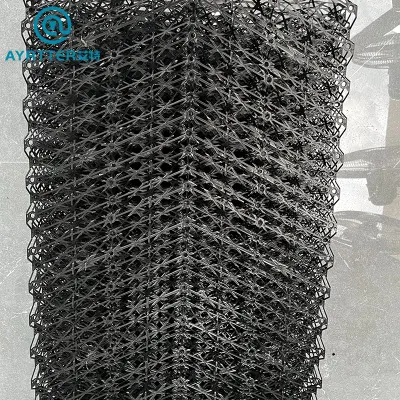

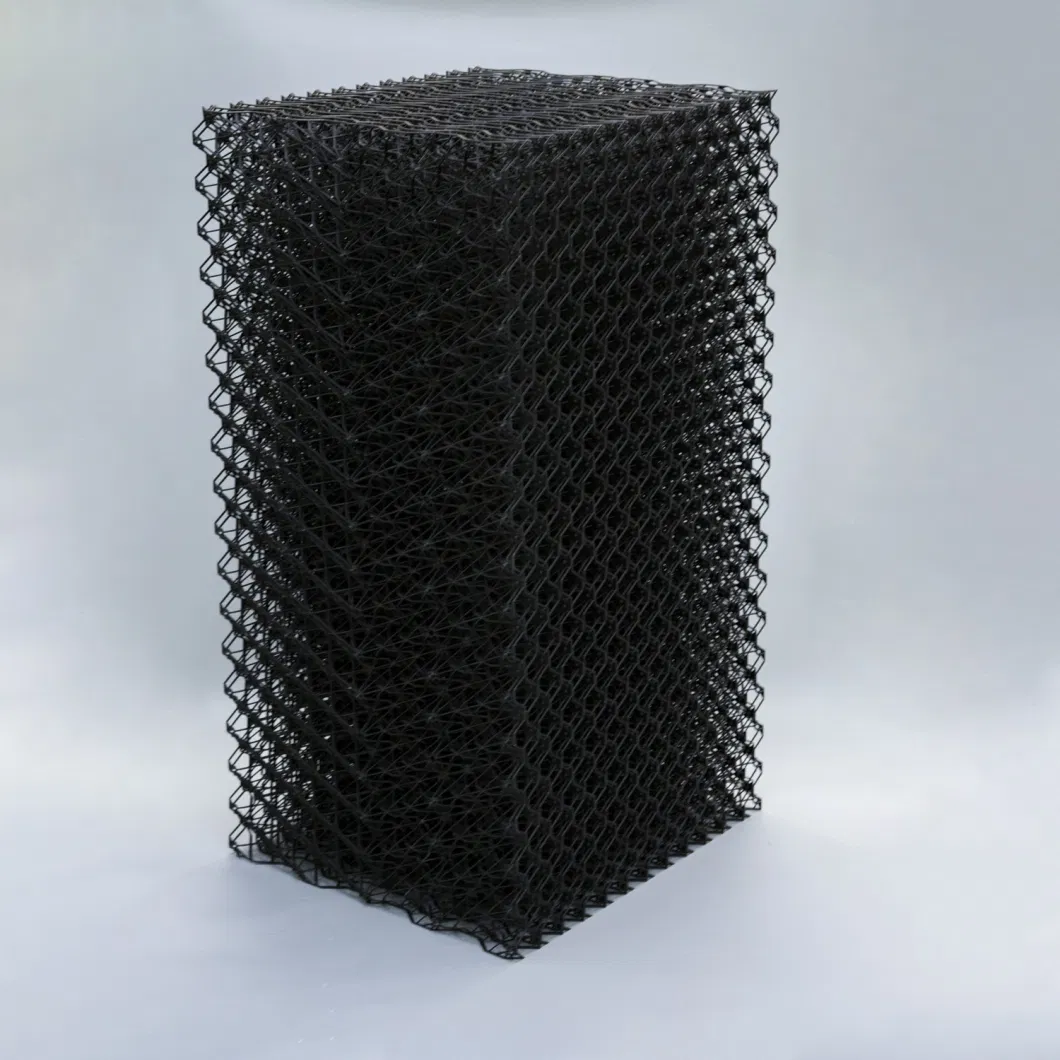

High Quality cooling pad PP Net Filler for Animal Husbandry Deodorization

Deodorization Plastic Cooling Pad is different from film filler & grid filler. Unique mesh-designed can achieved liquid drop quickly Polymerization and dispersion. The open cross-diagonal/vertical grid structure promotes high frequency contact and renewal of gas and liquid, overcomes filler, clogging and improve the overall cooling performance significantly.It is very suitable in cooling tower, agricultural and highly complex mass transfer applications.Injection molded from virgin plastic, it is a new deodorant product optimized on the basis of paper water curtains. In addition to deodorizing function, the plastic deodorizing wet curtain is also waterproof, mildew-proof, insect-proof and easy to clean with long service life.

Feature:

1) Products suitable for inferior water qualities

2) Chemical and high temperature resistance of Polypropylene

3) High stability

4) Cleaning with high pressures cleaners possible

5) Long service life

6) Impact resistant

7) Environmentally friendly

8) Economical installation

1) Length: 900mm

2) Width: 450mm

3) Flute: 19mm

4) Special heating exchange area: 125 square meter / cubic meter

5) Thickness: 1.8mm

6) Conection: wedged joint

7) Maximum total suspended solid: 300 ppm continuoous operation and can be bear under 500 ppm within 10 hours

8) Usage life: ≥ 20 years

Intelligent Stereoscopic warehouse

Intelligent Stereoscopic warehouse

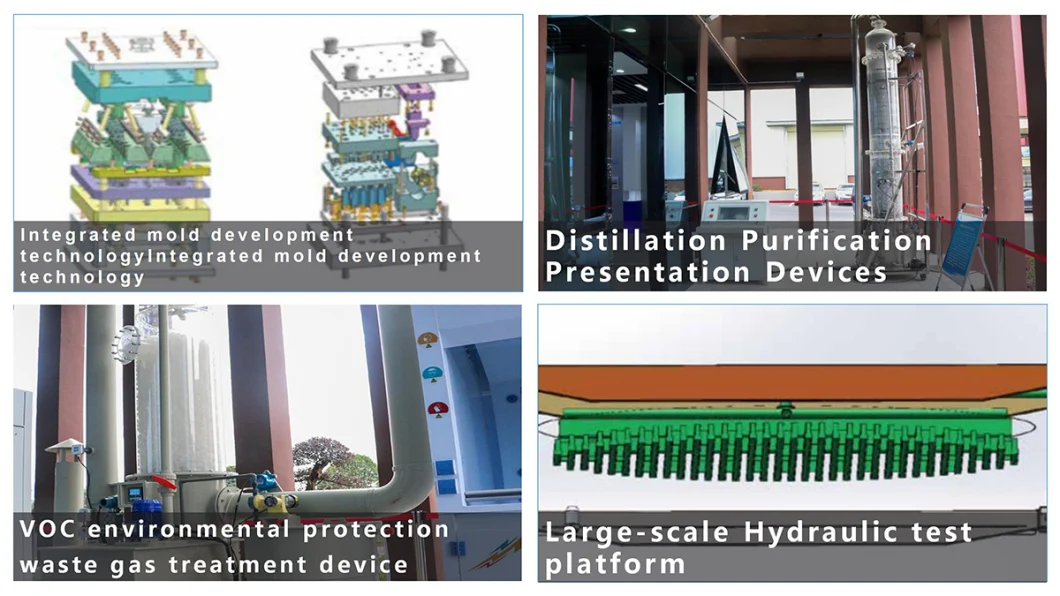

We have built up the single cargo space largest intelligent warehouse in China, which is calculated and managed by WMS,WCS system. The whole integrated workshop through AGV automatic distribution, The covered area is 3100 square meters, height of 24 meters and a capacity of 80000 cubic meters that can store 20000 cubic meters of finished products & 3000 ton of raw material.

Precision mold workshop

The workshop is equipped with the CNC machining center ,CNC engraving machine,large-scale electric pulse machine lathe,NC lathe,medium speed wire-cut EDM and a batch of high-end machine tool processing equipment. we have developed a multi slide automatic repair free technology of 1 million times, and developed a multi process integrated stamping repair free technology of 500000 times.

Plastic Random Packing Workshop

The injection molding workshop has 28 advanced production lines in the world. It adopts European standard large tonnage precision injection molding machine, equipped with three-axis servo manipulator, visual monitor and centralized feeding system to ensure that the annual output of

100000 cubic meters of finished products without any quality problems.

Metal Random packing Workshop

Metal integrated stamping workshop has 22 The original multi process integrated stamping die is equipped with intelligent detection device, which is free of maintenance for 300000 times .

Tower internals workshop

The workshop is equipped with 2 * 6m 3000W large laser cutting equipment, servo CNC bending machine, CNC turret punch, laser welding machine, shearing machine and other high-end equipment. The workshop has an annual output of 8000 tons of trays and internals, and is equipped with automatic degreasing and pickling purification line to meet the different needs of customers and keep improving.

Q1:What's the MOQ?

Q1:What's the MOQ?