- Overview

- Product Description

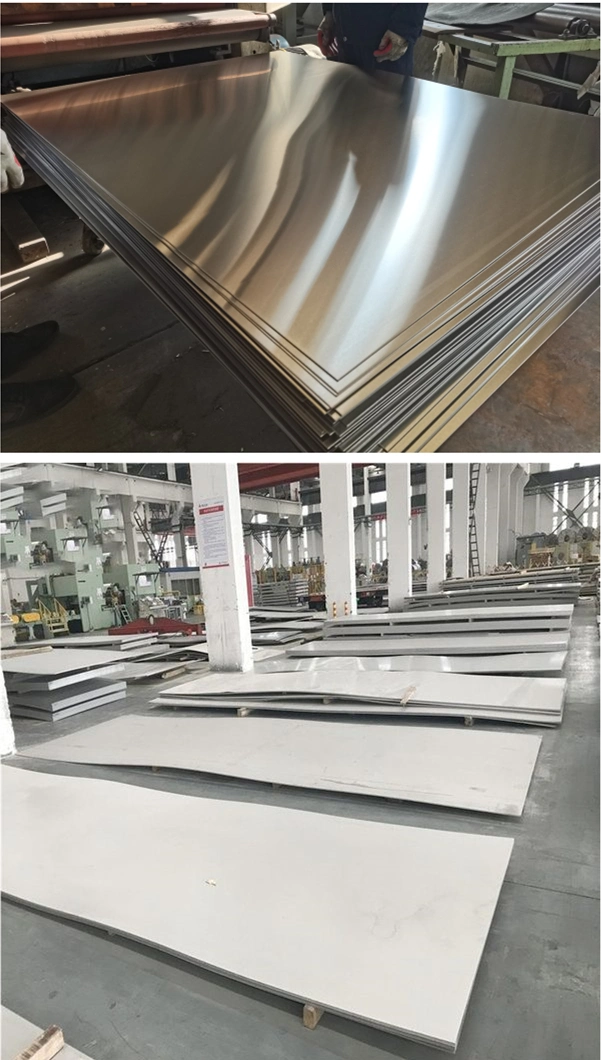

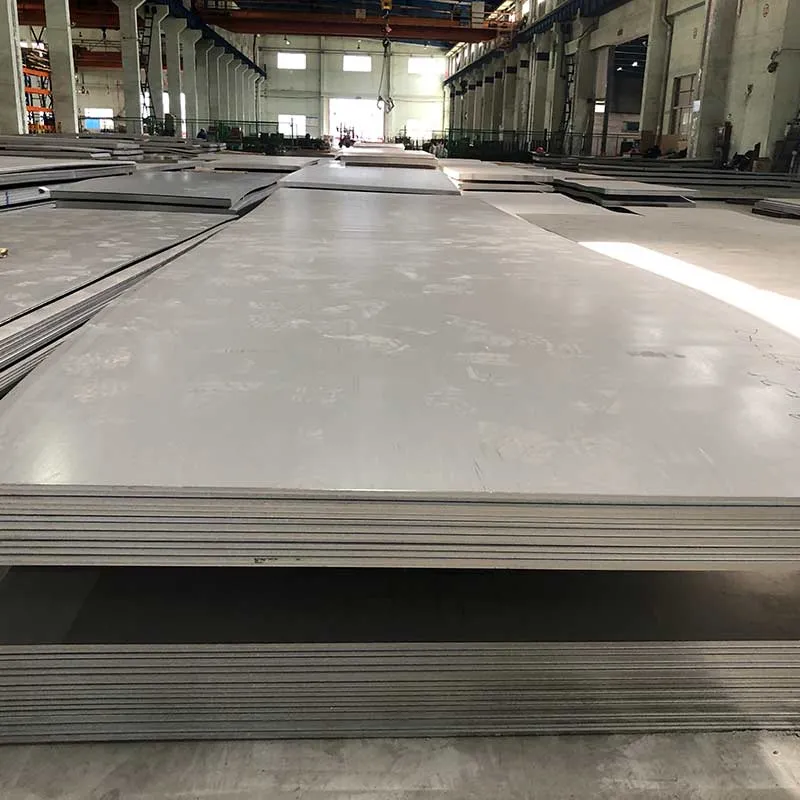

- Detailed Photos

- Packaging & Shipping

- Company Profile

- Certifications

- FAQ

Basic Info.

Product Description

Cold rolling is usually done by longitudinal rolling. The process of cold rolling production generally includes raw material preparation, pickling, rolling, degreasing, annealing (heat treatment), finishing, etc. Cold rolling takes hot-rolled products as raw materials, and the raw materials should be dephosphorized before cold rolling to ensure the clean surface of cold rolled products. Rolling is the main process to make the material deformation. The purpose of degreasing is to remove the lubricating grease attached to the rolling material when rolling, so as not to contaminate the surface of the steel when annealing, also for stainless steel to prevent carbon increase. Annealing includes intermediate annealing and finished heat treatment, intermediate annealing is through recrystallization to eliminate the work hardening generated by cold deformation, in order to restore the plasticity of the material and reduce the deformation resistance of the metal. The purpose of the finished product heat treatment in addition to the elimination of hardening by recrystallization.

Hot continuous rolling can be divided into ordinary carbon structural steel, low alloy steel and alloy steel according to its material and performance. According to different uses, it can be divided into: cold forming steel, structural steel, automobile structural steel, corrosion-resistant structural steel, mechanical structural steel, welded gas cylinder and pressure vessel steel, pipeline steel, etc.

| Product Name | Prime Quality Food-Grade Cold Rolled 0.6 0.8 1.2mm Thickness Stainless Steel Sheet 304 304L 316 316L With 2B BA Surface For Kitchen | ||

| Capacity | 10000 tons/month | ||

| Width | 200- 2000 mm | ||

| Thickness | 0.5-4mm Cold rolled, 4.5- 35mm Hot rolled | ||

| Material | 200 Series/300 Series/400series | ||

| Surface | Polished | ||

| Payment | T/T or L/C | ||

| Packing | Standard Sea-worthy Packing | ||

| MOQ | 5 tons | ||

Standard Sea Package or Customized.

Jiangsu Xinyong Metal Products Co., Ltd. is a large-scale joint-stock steel company in Shanghai China,with a registered capital of US$31.88 million, specializing in the production and sales of steel products. Xinyong's main products include stainless steel pipes, stainless steel plates, galvanized steel plates, galvanized steel coils, color steel tiles, aluminum plates, carbon structural steels, low-alloy structural steels, seamless pipes, welded pipes, rebars, etc. Xinyong has advanced steel production equipment, a complete ISO 9001:2000 and ISO 14001:2004 certified quality control system and an excellent after-sales service system.

Jiangsu Xinyong Metal Products Co., Ltd. is a large-scale joint-stock steel company in Shanghai China,with a registered capital of US$31.88 million, specializing in the production and sales of steel products. Xinyong's main products include stainless steel pipes, stainless steel plates, galvanized steel plates, galvanized steel coils, color steel tiles, aluminum plates, carbon structural steels, low-alloy structural steels, seamless pipes, welded pipes, rebars, etc. Xinyong has advanced steel production equipment, a complete ISO 9001:2000 and ISO 14001:2004 certified quality control system and an excellent after-sales service system.

Our products are exported to more than 80 countries and regions.Including Europe,Latin America ,Southeast Asia, Middle East, Africa,Australia and so on.

Xinyong has successively undertaken oil and gas pipeline construction projects in Russia, Malaysia, Mauritius, South Africa, Kenya, Nigeria, UAE, Mexico, and has accumulated rich experience in overseas project operation, product and service supply, and government bidding market. Xinyong has the ability to meet the customized needs of steel products according to different size and quality requirements.

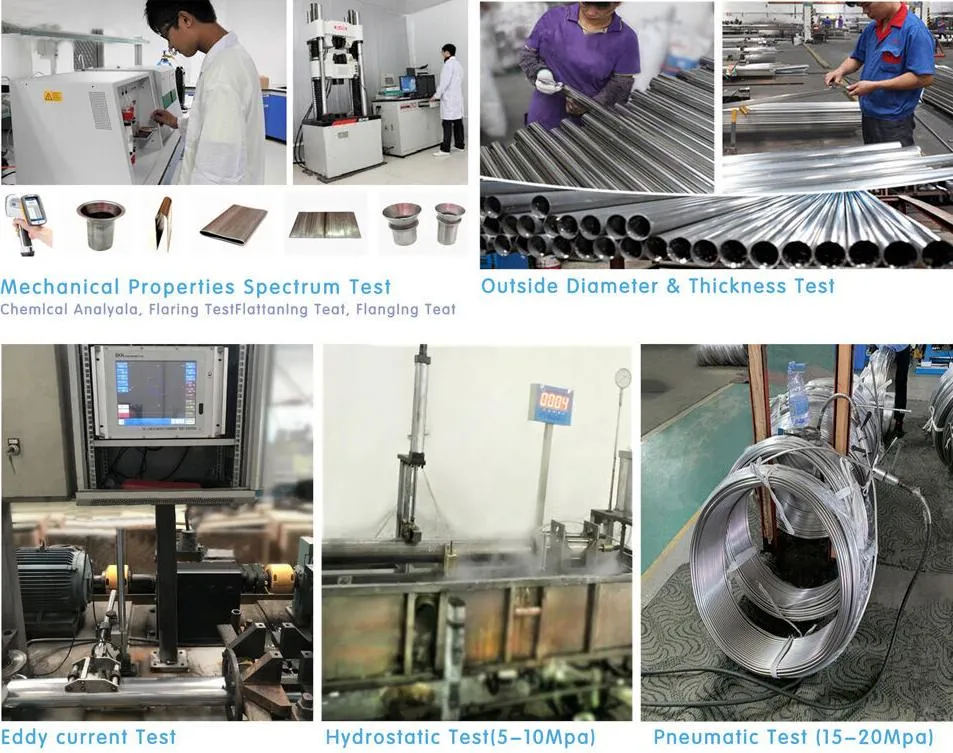

In addition to professional testing and certification, our factory also has its own testing department to ensure the quality of the goods.

In addition to professional testing and certification, our factory also has its own testing department to ensure the quality of the goods.

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Shanghai, China

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, L/C at sight can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.