Basic Info.

Product Description

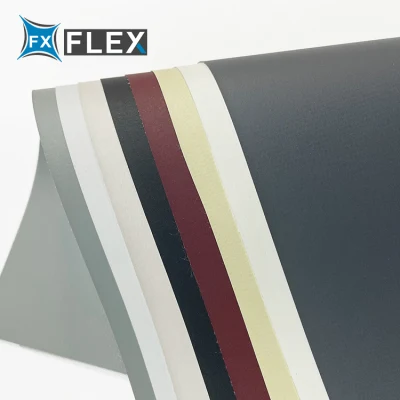

Features: A. Can be made into transparent or colored, hard or soft PVC particles, with cold resistance, UV resistance, anti-patina, conductive, high transparency and other characteristics. B products can meet the requirements of European REACH standard, European 2005/84/EC standard, American FDA standard, European RoHS standard, PAHs standard, bisphenol A standard, European and Japanese toy safety standard and American UL standard. C. The products are suitable for injection molding, extrusion, blow molding and other production and processing requirements. Annual production capacity of 20,000 tons. Purpose: Medical granules are widely used in making infusion tubes.

Tape: | SG1 | SG2 | SG3 | SG4 | SG5 | SG6 | SG7 | SG8 |

K value | 77-75 | 74-73 | 72-71 | 70-69 | 68-66 | 65-63 | 62-60 | 59-55 |

Viscosity, ml/g | 156-144 | 143-136 | 135-127 | 126-119 | 118-107 | 106-96 | 95-87 | 86-73 |

Average polymerization |

|

| 1350-1250 | 1250-1150 | 1100-1000 | 950-850 | 950-850 | 750-650 |

Number of impurity particle max | 30 | 30 | 30 | 30 | 30 | 30 | 40 | 40 |

Volatiles content % max | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 |

Appearing density g/ml min | 0.42 | 0.42 | 0.42 | 0.42 | 0.42 | 0.45 | 0.45 | 0.45 |

Residual after sieve 0.25mm mesh max | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

0.063mm min | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

Number of grain/400cm2 max | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

Plasticizer absorbency value of 100g resin | 25 | 25 | 25 | 22 | 19 | 16 | 14 | 14 |

Whiteness % min | 74 | 74 | 74 | 74 | 74 | 74 | 70 | 70 |

Residual chlorethylenecontent mg/kg max | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

Etc mg/kg max | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

Application:

PVC resin - SG3 K-Value 72-71, Average degree of polymerization 1350-1250

PVC resin - SG4 K-Value 70-69, Average degree of polymerization 1250-1150

PVC resin - SG5 K-Value 68-66, Average degree of polymerization 1100-1000

PVC resin - SG6 K-Value 65-63, Average degree of polymerization 950-850

PVC resin - SG7 K-Value 62-60, Average degree of polymerization 850-750

PVC resin - SG8 K-Value 59-55, Average degree of polymerization 750-650

SG-1 is used in producing high-grade electrical insulating material

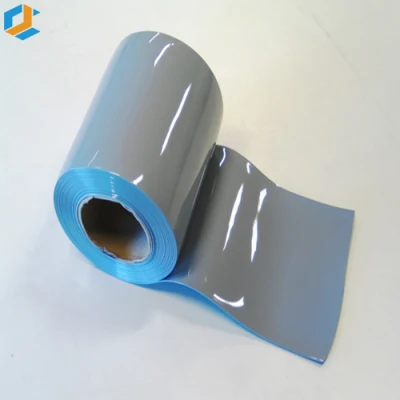

SG-2 is used in producing electrical insulating material, common soft products and film

SG-3 is used in producing electrical insulating materials, agricultural film, daily-use plastic products,

SG-4 is used in producing membranelle for industrial and civil use, tube and pipes

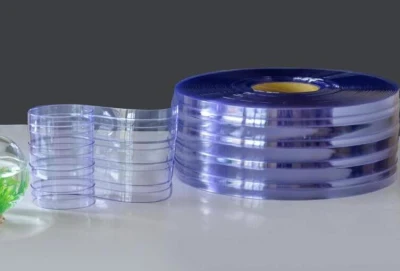

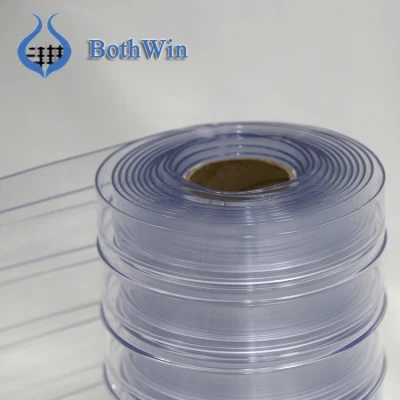

SG-5 is used in producing transparent products section bar, hard tube and decorative materials

SG-6 is used in producing clear foil, hard board and welding rod

SG-7, SG-8 is used in producing clear foil, hard injection molding.

En-71 RoHS SGS REACH

100% PVC

Packaging & Shipping:

Shipping by Sea, 20pallets in one 20GP.

Product Series

white masterbatch

It is widely used in injection molding, extrusion molding, blow molding and other production

processes. We can also tailor-made according to the specific requirements of customers, and

can provide , REACH, RoHstest reports of internationally recognized testing institutions

according to customer requirements.

black masterbatch

This product has high concentration and strong dispersibility , competitive price, strong applicability, suitable for PP, PE, ABS, TPU, PC and other materials.

color masterbatch

The color masterbatch produced by Jiangzhi Company adopts a unique process. Good, strong coloring ability and meet environmental protection requirements.

functional masterbatch

Jiangzhi uses advanced technology and rich practical experience to formulate various functional masterbatch, including anti-aging, anti-ultraviolet, anti-static, opening, smooth, matting of various carriers and other functional masterbatches, we also meet the needs of customers'product research and development .

Packing & Delivery

25kg PP bags or 1Tons bags

To better ensure the safety of your goods , professional,environmentally friendly , convenient and efficient packaging services will be provided.

Lead Time

| Quantity(tons) | 1-500 | 501-1000 | 1001-50000 | >50000 |

| Lead time(days) | 3 | 5 | 20 | To be negotiated |

FAQ

Q1: Can I get samples?

A: Yes! Samples can be arranged for those available products.

Q3:What is your packing?

A:Basically our packing is in 25/KG bags.

Q4:What is the normal lead time?

A: We will send goods to departure port within 5-10 workdays after we receive your payment.

1. Our staff are all experienced in Plastic Raw Material and chemical products who have related major background.

2. We can assure the same specification as sample before you place commercial order.

3. Third Party can inspect according to your requirement before shipping.

Q6:If any quality problem, how can you settle it for us?

A:When discharging the container, you need to inspect all the goods. If anybreakage or defect products were found, you MUST take the pictures fromthe original carton. All the claims must be presented within 7 working days after discharging the container.This date is subject the arrival time of containr. We will advise you to certify the claim by third party,or we can accept the claim from the samples or pictures you present, discharging of the containeris not included. Finally we will completely compensate all your loss.

Q7: Do you have any other plastic raw material or chemicals?

A: Yes, We can provide kinds of such as PP, PE,PVC,PET,ABS ,EVA,PC,etc...

If you still have questions,contact with us~